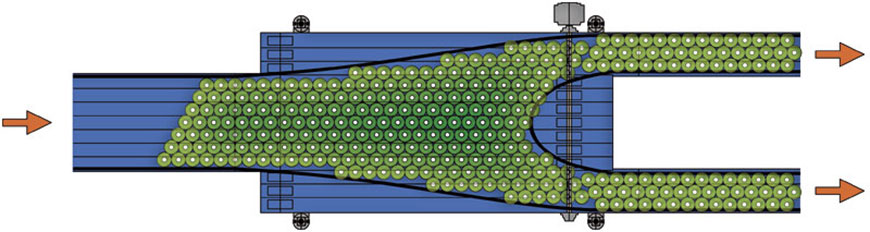

Fluid transport of the products

The transport of containers and products from a machine to another one within a bottling line is a crucial factor in order to ensure high performance standards. This procedure must be fluid and constant and must guarantee the maximum operating flexibility, in order to face sudden flow changes, due to unexpected conditions during the machines operation. To this purpose, a last generation automation and control system, as well as sophisticated sensors, ensure high performance standards during all phases of the production cycle.

SMI logistic systems are designed to fully meet the exigencies of fluidity, flexibility and efficiency, thanks to innovative technical solutions and top quality materials:

- modular structure which can easily fit several types of containers and product flows

- minimization of the changeover times, in order to quickly switch from a production to another one

- high operational reliability, thanks to stainless steel AISI 304 frame and components

- friction and noise levels among the lowest in this sector

- reduced need of maintenance and cleaning interventions, restricted to a few sections

- easy and intuitive start and control operations

- user-friendly technology, thanks to the POSYC operator panel with LCD touch screen

- energy consumption and operational costs among the lowest of the market.

SMI solutions can guarantee an optimal control of the product flows, thanks to an accurate study of the accumulation, distribution and transport dynamics.

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A.

IVA SMI INDUSTRIES Group

Headquarters: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Registered office: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

VAT: 04471940165 - TAX code: 03942700166 - R.E.A.: 421708

Share capital: Euro 5.000.000 i.v.