Hyper-clean electronic fillers

HEVS series (carbonated products)

HEVS - Electronic volumetric filling system

The thirty-year experience of Enoberg (company part of the SMI Group) in the manufacturing of fillers and the growing market demand in terms of hygiene, reliability, simplicity of machine maintenance and use have led the company to manufacture the new HEVS range (Hyper-clean Electronic Volumetric filling systems for Sparkling products).

The volumetric electronic filling system is based on the use of a flow meter for each filling valve. The flow meter detects the flow of the product that fills each bottle; once the correct volume is reached, the flow meter controls the closing of the filling valve.

The products that can be worked by HEVS fillers are:

- carbonated water

- CSD (carbonated drinks)

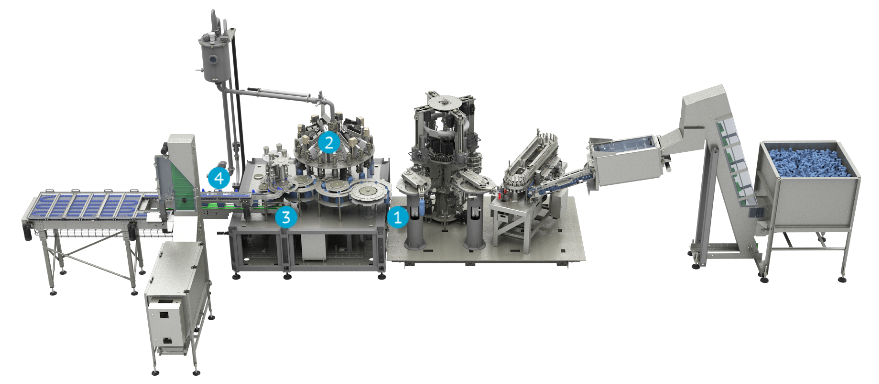

1Empty bottles transfer

After being manufactured by the stretch-blow moulding machine, empty bottles are conveyed from the blower to the filler by "neck-handling" direct transfer by menas of adjoining star wheels. The star-wheel at the blowmoulder outlet is equipped with grippers electronically synchronised with the brackets of the starwheel at the filler inlet.

2 Filling

Once the filling station is reached, a gripper, directly connected with the filling valve, grabs the bottle by the neck and brings it into contact with the filling valve, in order to allow the filling operation. The product to be filled is positioned in a manifold resistant to high pressure, placed inside the filling carousel.

In the bottle, in contact with the filling valve, CO2 is injected in order to take it to the right pressure and have a filling with no froth. The electronic volumetric filling process is carried out through flow meters, placed upstream of each filling valve. During the filling process, the flow meter detects the amount of product that goes through the valve. The measurement is based on pulses, that are compared to the ones set for the format in use. While the product enters the bottle, the CO2 goes out through the dedicated channel.

When the set value is reached, the closure sign is sent to the filling valve. At this point the decompression/sniff phase starts: a specific channel conveys the pressure left in the bottle to a dedicated manifold that discharges outside the filling section.

At this stage the bottle is transferred to the capper.

3Capping

A shaped star wheel allows to center the bottle under its capping station. The cap coming from the feeding system is picked by a transfer star wheel called “pick and place”. The capping head picks the cap from the star wheels and applies it to the bottle. According to the cap to be applied (plastic screw cap or pressure cap), the capping system can operate by rotation or pressure.

The filled and capped bottle is transferred to the outfeed conveyor.

4Outfeed conveyor

The filled and capped bottles are transferred to a chain conveyor that conveys the bottles outside the machine. This conveyor is equipped with an automatic height adjusting system, that allows to adjust the bottle base according to the bottle height.

- Frame made of AISI 304 stainless steel

- Tempered glass safety guards and sealing gaskets that hermetically seal the filling environment from the external one

- Dummy bottle positioned directly on the filling valve with automatic activation

- High-precision flow meters installed next to the filling valves

- Filling valve fully made of AISI 316 and characterized by an easy maintenance

- The manifold is equipped with: fully washable and sanitized CO2 charging/discharging valve; capacitive level probe, that communicates with the modulating valve in product infeed in order to keep the product level in the manifold constant

- Quick format changeover of the bottle guide equipment

- Parameters of each format directly controlled through HMI

- 7'' HMI touch screen (15'' available as an option)

Maximum filling precision

The filling process is extremely precise, thanks to the use of the flow meter, an electronic device installed near each valve that detects the flow of the product that fills each bottle by counting the pulses and sends the filling valve the closure sign, once the value of the format in use is reached.Compact filling module

The compact filling module allows to minimize the number of transfer star wheels, ensuring at the same time practical access to the machine for maintenance and washing operations.Cutting-edge filling valve

Filling valve with a high technological content with an independent channel for the passage of CO2 inside the bottle. Furthermore, the valve terminal allows to divert the product flow to the bottle walls and therefore to reduce the liquid turbulence.Fully washable filling valve

Fully sanitized filling valve thanks to dummy bottles with manual or automatic (optional) positioning.High level of hygiene and reduction in maintenance times

Filling piston integrated in the valve body ensures less bottle movement, a higher level of hygiene and a reduction in maintenance times.Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA