Sustainable production processes. Sant Aniol chooses the EBS 8 KL ERGON stretch-blow moulder

| |||

Sant Aniol chooses the EBS 8 KL ERGON stretch-blow moulder | |||

| Founded in 1993, Sant Aniol has always operated with a focus on sustainability, striving to preserve nature and make the world a better place to live.

| |||

Bottles with a volcanic spirit | |||

| Sant Aniol PET containers feature a distinctive and elegant design that conveys the unique qualities of the water whose spring is located within the Natural Park of Garrotxa, at a depth of more than 120 meters, in a place characterized by sedimented lava and volcanic rocks that give the water its purity and excellent qualities. | |||

| |||

SMI solution for Sant Aniol | |||

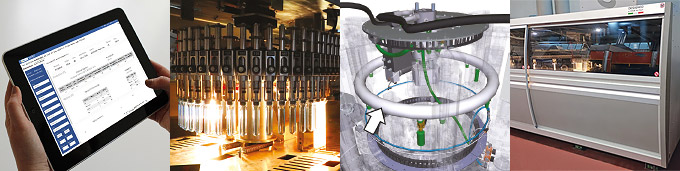

| To safeguard the environment, Sant Aniol adopts state-of-the-art technologies designed to maximize energy efficiency. Fifteen years after the first supply, the Spanish company once again turned to SMI for the installation of a new EBS 8 KL ERGON rotary stretch-blow moulder, intended for the bottling line of natural mineral water in 0.33 L, 0.5 L, and 1.5 L PET containers. | |||

| |||

Environmental benefits

The EBS 8 KL ERGON stretch-blow moulder installed at the Girona plant is fitted with stretch-blow moulds equipped with the special “ReduxAir” bottom, which, through special technical and design measures, allows the air between the outer walls of the bottle and the surface of the mould to be released more quickly, making it possible to produce rPET/PET containers with lower air pressures, especially: - 0.33 L containers at 15 bar air pressure | |||

| |||

Energy efficiency benefits

The EBS 8 KL ERGON stretch-blow moulder supplied by SMI is equipped with an energy counter with a digital LCD display, which, through the control of energy consumption, enables the optimization of the operational efficiency of the plant. The counter installed on the machine is used to record and display, alternately, electricity consumption, voltage, current and power over a given period. Thanks to these devices, the solutions supplied by SMI can leverage the services offered by the platform SmyIoT, an interactive database that remotely collects, verifies, processes and enhances all operating parameters of the plant, both at the level of individual machines and across the entire production line. This allows users to improve operational efficiency and energy performance across all processes, schedule maintenance interventions and reduce overall production costs. | |||

| |||

| For further information on the latest news from SMI on sustainable development, contact our sales department or visit our website

| |||

Contactez-nous

- SMI S.p.A.

- Adresse: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Lundi - Vendredi: 07:45 - 17:30

Samedi - Dimanche: Fermé

Informations sur la privacy

PROTECTION DONNEES ET PRIVACY

Depuis le 25 mai 2018 le Règlement Européen 679/2016 (RGPD) est entré pleinement en application, définissant les règles générales pour la protection des données personnelles. Il s'agit d'une étape importante, qui fixe les mêmes règles pour le traitement des données personnelles pour tous les Pays de l'Union Européenne. Chaque société du Groupe SMI a développé une série de procédures d'adaptation aux nouvelles règles, tout en révisant les structures ou les modalités opérationnelles pour mettre en pratique les règles de protection des données personnelles. Voici quelques initiatives pour l'application du Règlement à partir du 25 mai 2018 et notre procédure de traitement des données personnelles.

![]()

Licéité du traitement

Le Groupe SMI a établi la base juridique pour le traitement des données personnelles (consentement, exécution des obligations contractuelles, intérêts vitaux des personnes concernées ou de tiers, obligations auxquelles est soumis le titulaire, intérêt public ou exercice de l'autorité publique, intérêt légitime supérieur du titulaire ou de tiers auxquels les données sont communiqueés).

![]()

Dossier d'information

Les sociétés du Groupe SMI ont enrichi, amélioré et adapté aux nouvelles règles le dossier d'information à fournir aux personnes concernées (articles 13 et 14 RGPD).

![]()

Droits des personnes concernées (accès, oubli ou effacement, limitation du traitement, opposition, portabilité)

Le Groupe SMI a adopté des mesures techniques et organisationnelles pour favoriser l'exercice des droits et la réponse aux demandes envoyées par les personnes concernées.

![]()

Responsable du traitement

Sur la base du nouveau principe de "responsabilité", les sociétés du Groupe SMI ont redéfini leur organisation pour garantir le respect pro-actif du règlement. On a redéfini le rôle du responsable du traitement et des fournisseurs de services, dont l'activité implique le traitement des données personnelles.

![]()

Risque du traitement et mesures de “responsabilité” adoptées par les responsables du traitement (évaluation d'impact, registre des activités de traitement, mesures de sécurité, violation des données personnelles)

Grâce à un “Document de conformité” incluant le registre des activités de traitement, le Groupe SMI planifie, met en oeuvre et démontre toutes les mesures de sécurité, techniques et organisationnelles, adaptées aux caractéristiques du traitement et prévoit les mesures nécessaires pour notifier la violation des données.

![]()

Transfert international des données

Le Groupe SMI s'engage à respecter les principes généraux et les garanties pour le transfert des données vers des Pays Tiers.

Le responsable du traitement est:

SMI S.p.A.

Bureaux administratifs: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

Pour toute information, écrivez à: privacy@smigroup.net

Le Règlement Européen 679/2016 autorise à l'exercice des droits expressément prévus pour les personnes concernées.

Veuillez trouver ci-joint le texte intégral des articles 15; 16; 17; 18; 20; 21; 77 du Règlement, qui définissent les droits et les modalités d'exercice.

Afin d'exercer vos droits, veuillez envoyer le formulaire dûment rempli à l'adresse du Responsable du traitement.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA