New EBS KL ERGON: efficiency and sustainability in a small space

| |||

| Energy efficiency and environmental sustainability play a key role in the investment choices of every company. | |||

| At Drinktec trade fair, that will be held in Munich (Germany) from 12-16 September 2022, SMI will present the new EBS KL ERGON compact stretch-blow moulder for production requirements up to 2,500 bottles/hour per cavity.

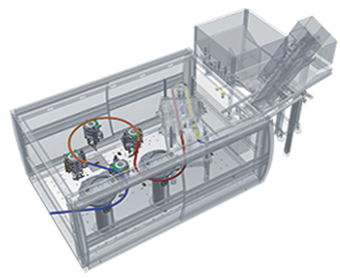

Inspired by Industry 4.0 and Internet of Things (IoT) principles, the new EBS KL ERGON series, available in stand-alone, as well as in ECOBLOC® version (integrated with a rotary electronic filler and a rotary capper), is the ideal solution for the production of PET and rPET containers up to 25,000 bottles/hour. |  | ||

| |||

The advantages of EBS KL ERGON range at a glance

| |||

| Advanced technology in a small spaceThe new EBS KL blow moulder stands out for its ultra-compactness, made possible by the fact that the preform heating section and the stretch-blow moulding section are integrated in a single module. - space-saving design suitable even for small-sized bottling lines | ||

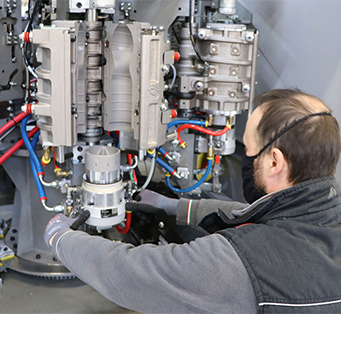

Environmental sustainable production processesThe stretch-blow moulding carousel of the new EBS KL blow moulders is equipped with motorized stretch rods, whose functioning, controlled by electronic drives, do not require pneumatic cams. - precise management of the stretch rod path and accurate control of its position |  | ||

| Maximum efficiency and precisionCam-free technology that allows to modify the stretch speed without mechanical interventions (cam replacement), as the servo-motor automatically adjusts according to the production speed. -reduction of the machine vibrations | ||

Energy saving and reduced maintenanceThe stretch-blow moulding system of the new EBS KL blow moulders are equipped with high-performance valves with low dead volumes (-50% compared to the previous models). -reduction of pre-blowing and blowing times, which ensures a higher performance of the machine and a better quality of the bottles produced |  | ||

| Fast and precise movements

New motion system of the grippers, based on preform/bottle grippers without springs, equipped with desmodromic cams. -technical innovation that optimizes the spaces and reduces the diameter in which the grippers move, which leads to a lower wear and a higher control precision of the blow moulder | ||

| For further information on the new EBS KL ERGON blowers, contact our sales department or visit our web site. | |||

Contactez-nous

- SMI S.p.A.

- Adresse: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Lundi - Vendredi: 07:45 - 17:30

Samedi - Dimanche: Fermé

Informations sur la privacy

PROTECTION DONNEES ET PRIVACY

Depuis le 25 mai 2018 le Règlement Européen 679/2016 (RGPD) est entré pleinement en application, définissant les règles générales pour la protection des données personnelles. Il s'agit d'une étape importante, qui fixe les mêmes règles pour le traitement des données personnelles pour tous les Pays de l'Union Européenne. Chaque société du Groupe SMI a développé une série de procédures d'adaptation aux nouvelles règles, tout en révisant les structures ou les modalités opérationnelles pour mettre en pratique les règles de protection des données personnelles. Voici quelques initiatives pour l'application du Règlement à partir du 25 mai 2018 et notre procédure de traitement des données personnelles.

![]()

Licéité du traitement

Le Groupe SMI a établi la base juridique pour le traitement des données personnelles (consentement, exécution des obligations contractuelles, intérêts vitaux des personnes concernées ou de tiers, obligations auxquelles est soumis le titulaire, intérêt public ou exercice de l'autorité publique, intérêt légitime supérieur du titulaire ou de tiers auxquels les données sont communiqueés).

![]()

Dossier d'information

Les sociétés du Groupe SMI ont enrichi, amélioré et adapté aux nouvelles règles le dossier d'information à fournir aux personnes concernées (articles 13 et 14 RGPD).

![]()

Droits des personnes concernées (accès, oubli ou effacement, limitation du traitement, opposition, portabilité)

Le Groupe SMI a adopté des mesures techniques et organisationnelles pour favoriser l'exercice des droits et la réponse aux demandes envoyées par les personnes concernées.

![]()

Responsable du traitement

Sur la base du nouveau principe de "responsabilité", les sociétés du Groupe SMI ont redéfini leur organisation pour garantir le respect pro-actif du règlement. On a redéfini le rôle du responsable du traitement et des fournisseurs de services, dont l'activité implique le traitement des données personnelles.

![]()

Risque du traitement et mesures de “responsabilité” adoptées par les responsables du traitement (évaluation d'impact, registre des activités de traitement, mesures de sécurité, violation des données personnelles)

Grâce à un “Document de conformité” incluant le registre des activités de traitement, le Groupe SMI planifie, met en oeuvre et démontre toutes les mesures de sécurité, techniques et organisationnelles, adaptées aux caractéristiques du traitement et prévoit les mesures nécessaires pour notifier la violation des données.

![]()

Transfert international des données

Le Groupe SMI s'engage à respecter les principes généraux et les garanties pour le transfert des données vers des Pays Tiers.

Le responsable du traitement est:

SMI S.p.A.

Bureaux administratifs: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

Pour toute information, écrivez à: privacy@smigroup.net

Le Règlement Européen 679/2016 autorise à l'exercice des droits expressément prévus pour les personnes concernées.

Veuillez trouver ci-joint le texte intégral des articles 15; 16; 17; 18; 20; 21; 77 du Règlement, qui définissent les droits et les modalités d'exercice.

Afin d'exercer vos droits, veuillez envoyer le formulaire dûment rempli à l'adresse du Responsable du traitement.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA