Compactness and sustainability at Anuga FoodTec

| |||

Compact and efficient end of line for the food industry | |||

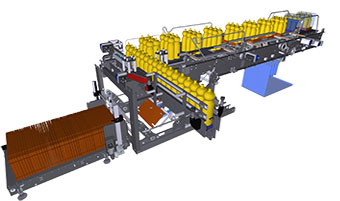

| At Anuga FoodTec 2022, that will be held from 26th to 29th April in Cologne (Germany), SMI will showcase an extremely compact, efficient and environmentally sustainable end-of-line system, composed of an ASW 30 T ERGON shrink wrapper with single-lane infeed and 90° product entry and of the APS 615 ERGON semi-automatic palletizer. The solutions showcased at Anuga FoodTec pack metal containers of tomato soup in 4x3 format in tray+100 % recycled film, that are then palletized by the new “mini-pal” at the speed of 15 packs/minute. | ||

| This system has been designed for those food manufacturers who do not require high speeds, have a reduced-size plant and a limited budget, but at the same time do not want to give up the advantages offered by Industry 4.0 and Internet of Things (IoT)- compliant advanced technologies.

| |||

| |||

Meet us at booth C088 Hall 5.1 | |||

THE ADVANTAGES OF THE ASW SERIES | |||

CompactnessThe ASW ERGON range is the ideal solution for packing a wide range of containers with a cylindrical, oval or square/rectangular base. Thanks to the single-lane infeed conveyor, a divider for channeling the product at the infeed is not required. The machine occupies very little space and easily adapts to the logistic conditions of any line layout.

|  | ||

| Ergonomics and safetyThe single-lane infeed facilitates the correct channeling of loose containers on the conveyor belt. Thanks to the rotary feeding device, the containers are moved from the single-lane conveyor to the multi-lane conveyor at the machine infeed. The pack formation is characterized by a double belt system, that, by means of an electronic cam, separates the products according to the format to be processed. The cardboard magazine (for P and T models), located in an easily accessible position for the operator, ensures an ergonomic, easy, fast and safe loading.

| ||

Flexibility and sustainabilityFormat changeover is easy and fast, as the adjustment of the guides of the different rows is not required. The film reel unwinding is controlled by a progressive brake, which ensures optimal film tensioning. The film splicing at the end of the reel is performed by a manual sealing bar and the cutting unit is equipped with a blade controlled by a direct-drive brushless motor, that ensures a precise cut and simplifies the maintenance. The model showcased at the trade fair uses a 100% recycled film with a 60 micron thickness, an environmentally sustainable solution for a high-quality pack. |  | ||

THE ADVANTAGES OF THE APS 615 ERGON MODEL | |||

| Compact and ergonomic structure

| ||

Easy flexibility and maintenance

-great operational flexibility -wide possibilities of customization, in order to adapt to the needs of format changeover, product changeover and/or plant layout. The electric panel is a separate module that is not unwired during the transport and can be immediately installed at the customer's premises.

|  | ||

| If you want to discover other advantages of SMI packaging solutions, we'll wait for you at Anuga FoodTec 2022 in Cologne at our booth C088, hall 5.1 or we invite you to contact our sales department. Marketing Department

| |||

Contáctanos

- SMI S.p.A.

- Dirección: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Lunes - Viernes: 07:45 - 17:30

Sábado - Domingo: Cerrado

Newsletter

© SMI S.p.A. 2026

Nota informativa sobre el tratamiento de tus datos personales - Legal notice

Nota informativa sobre el tratamiento de tus datos personales

PROTECCION DATOS Y PRIVACY

A partir del 25 de mayo de 2018 es totalmente aplicable el Reglamento Europeo 679/2016 (GDPR) que define las normas generales para la protección de datos personales. Este es un hito importante que introduce las mismas reglas para el procesamiento de datos personales para todos los países de la UE. Todas las empresas del Grupo SMI han promovido e implementado una actividad de ajuste seria, repensando estructuras o métodos operativos/organizativos, esforzándose por lograr la protección de datos personales "en la práctica". Las siguientes son algunas de las acciones tomadas para aplicar el Reglamento a partir del 25 de mayo de 2018 y nuestra política de procesamiento de datos personales.

![]()

Fundamentos de legalidad

Para todas las actividades de tratamiento, el Grupo SMI ha identificado la base legal (consentimiento, cumplimiento de obligaciones contractuales, intereses vitales del interesado o terceros, obligaciones legales a las que está sujeto el propietario, interés público o el ejercicio de la autoridad pública, el interés legítimo prevaleciente del titular o de terceros a quienes se comunican los datos).

![]()

Documentación informativa

Las empresas del Grupo SMI han enriquecido, mejorado y adaptado a las nuevas normas la información que se debe proporcionar a las partes interesadas (artículos 13 y 14 del RGPD).

![]()

Derechos de las partes interesadas (acceso, cancelación-olvido, limitación de procesamiento, oposición, portabilidad)

El Grupo SMI ha adoptado medidas técnicas y organizativas para promover el ejercicio de los derechos y la respuesta a las solicitudes de las partes interesadas.

![]()

Titular, responsable, encargado del tratamiento

A la luz del nuevo principio de "empoderamiento", las empresas del Grupo SMI han redefinido su organización para garantizar el cumplimiento proactivo de la regulación en su totalidad. Ha redefinido los roles de los actores de tratamiento y proveedores de servicios que involucran actividades de procesamiento basadas en comisiones.

![]()

Enfoque basado en el riesgo para el tratamiento y las medidas de " accountability" de los propietarios y gerentes (evaluación de impacto, registro de tratamiento, medidas de seguridad, violaciones de datos personales)

A través de un "Documento de Cumplimiento" que incorpora el registro de actividades de tratamiento, el Grupo SMI planifica, implementa y demuestra las medidas de seguridad, técnicas y organizativas "adecuadas" a las características del tratamiento y prepara los procedimientos necesarios para llevar a cabo, cuando sea necesario supuestos, la notificación del "data breach".

![]()

Transferencia internacional de datos

El Grupo SMI se compromete a respetar y adoptar los principios y garantías generales para la transferencia a terceros países.

El titular del tratamiento de datos es:

SMI S.p.A.

Oficina administrativa: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

Para información escriba a: privacy@smigroup.net

El Reglamento Europeo 679/2016 otorga el derecho a ejercer los derechos expresamente previstos para la persona interesada.

Adjuntamos el texto completo de los artículos. 15; 16; 17; 18; 20; 21; 77 del mismo Reglamento que describe el contenido y los métodos para ejercer estos derechos.

Para permitirle ejercer estos derechos, le pedimos que envíe el formulario de solicitud debidamente completado a la dirección del Propietario.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA