PET bottles in the circular economy

| |||

The role of PET bottles in the circular economy | |||

| Packaging sustainability is a key issue, in particular for the beverage industry, in which more and more questions have been raised about the material to be used for safe packaging, with limited impact on the environment.

| ||

| Recent studies have shown the benefits arising from the use of plastic bottles, since this solution is unbreakable, safe, with great barrier properties, lightweight and above all recyclable! In comparison with other packaging materials, such as glass or aluminium, PET has a good environmental profile, mainly thanks to its lightness that translates into less material to produce, less material to dispose of, less energy used to manufacture it and less fuel used for transporting packed products. Thanks to its recyclability and its great weight-capacity ratio, many producers of mineral waters and soft drinks promote and re-evaluate PET and r-PET as convenient and win-win solutions from the environmental sustainability point of view. | |||

| |||

R-PET or lightweight bottles? | |||

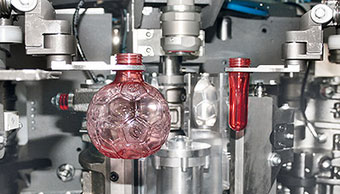

Ideal system for producing PET and r-PET bottles | |||

| The use of r-PET (recycled PET) for manufacturing new bottles is the core of the concept of circular economy, that consists of collecting materials after they have been used and processing them, so that they can be reused or recycled. Every time a PET container is recycled, its oil reserve is recovered and reused, eliminating the waste and reducing the packaging environmental impact, provided that efficient systems for managing waste and recycling exist. |  | ||

| Producing even lighter bottles

Another strategy that contributes to the environmental protection is based on the design of even lighter PET containers, that allow to save on plastics and that, indeed, fully comply with the environmental policy of most manufacturers of beverages. | ||

SMI solution for the “green factory”

The rotary, compact, efficient and ergonomic stretch-blow moulders from the EBS ERGON range perfectly meet these eco-friendly strategies and the new manufacturing paradigms of “smart & green factory” | |||

| Moreover, SMI designs containers and manufactures moulds. Thanks to a team of highly specialized engineers and latest generation tools, SMI is able to design, develop and virtually prototype a wide range of packaging solutions in rPET and PET, according to the customers' specific requirements.

|  | ||

| If you want to find out further advantages of the EBS ERGON stretch-blow moulders or ECOBLOC® ERGON stretch-blow moulding, filling and capping integrated systems, we invite you to contact our sales department or visit our website.

| |||

Contactez-nous

- SMI S.p.A.

- Adresse: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Lundi - Vendredi: 07:45 - 17:30

Samedi - Dimanche: Fermé

Informations sur la privacy

PROTECTION DONNEES ET PRIVACY

Depuis le 25 mai 2018 le Règlement Européen 679/2016 (RGPD) est entré pleinement en application, définissant les règles générales pour la protection des données personnelles. Il s'agit d'une étape importante, qui fixe les mêmes règles pour le traitement des données personnelles pour tous les Pays de l'Union Européenne. Chaque société du Groupe SMI a développé une série de procédures d'adaptation aux nouvelles règles, tout en révisant les structures ou les modalités opérationnelles pour mettre en pratique les règles de protection des données personnelles. Voici quelques initiatives pour l'application du Règlement à partir du 25 mai 2018 et notre procédure de traitement des données personnelles.

![]()

Licéité du traitement

Le Groupe SMI a établi la base juridique pour le traitement des données personnelles (consentement, exécution des obligations contractuelles, intérêts vitaux des personnes concernées ou de tiers, obligations auxquelles est soumis le titulaire, intérêt public ou exercice de l'autorité publique, intérêt légitime supérieur du titulaire ou de tiers auxquels les données sont communiqueés).

![]()

Dossier d'information

Les sociétés du Groupe SMI ont enrichi, amélioré et adapté aux nouvelles règles le dossier d'information à fournir aux personnes concernées (articles 13 et 14 RGPD).

![]()

Droits des personnes concernées (accès, oubli ou effacement, limitation du traitement, opposition, portabilité)

Le Groupe SMI a adopté des mesures techniques et organisationnelles pour favoriser l'exercice des droits et la réponse aux demandes envoyées par les personnes concernées.

![]()

Responsable du traitement

Sur la base du nouveau principe de "responsabilité", les sociétés du Groupe SMI ont redéfini leur organisation pour garantir le respect pro-actif du règlement. On a redéfini le rôle du responsable du traitement et des fournisseurs de services, dont l'activité implique le traitement des données personnelles.

![]()

Risque du traitement et mesures de “responsabilité” adoptées par les responsables du traitement (évaluation d'impact, registre des activités de traitement, mesures de sécurité, violation des données personnelles)

Grâce à un “Document de conformité” incluant le registre des activités de traitement, le Groupe SMI planifie, met en oeuvre et démontre toutes les mesures de sécurité, techniques et organisationnelles, adaptées aux caractéristiques du traitement et prévoit les mesures nécessaires pour notifier la violation des données.

![]()

Transfert international des données

Le Groupe SMI s'engage à respecter les principes généraux et les garanties pour le transfert des données vers des Pays Tiers.

Le responsable du traitement est:

SMI S.p.A.

Bureaux administratifs: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

Pour toute information, écrivez à: privacy@smigroup.net

Le Règlement Européen 679/2016 autorise à l'exercice des droits expressément prévus pour les personnes concernées.

Veuillez trouver ci-joint le texte intégral des articles 15; 16; 17; 18; 20; 21; 77 du Règlement, qui définissent les droits et les modalités d'exercice.

Afin d'exercer vos droits, veuillez envoyer le formulaire dûment rempli à l'adresse du Responsable du traitement.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA