Cartonatrici in scatole wrap-around con ingresso a 90°

Serie ACW ERGON

ACW 150-I ERGON - Confezionatrici in scatole wrap-around fino a 150 introduzioni/minuto

La serie ACW 150-I ERGON è costituita da cartonatrici wrap-around con ingresso a 90º monofilare, adatte alla realizzazione di pacchi in scatola wrap-around e vassoio (quest’ultimo con bordi della stessa altezza oppure di altezze differenti).

Queste macchine consentono di confezionare una vasta gamma di contenitori ovali, a base cilindrica oppure quadrata/rettangolare con velocità di produzione fino a 150 introduzioni per minuto, in funzione del modello di macchina e del tipo di prodotto da imballare.

I modelli di questa serie si contraddistinguono per la struttura compatta che si adatta facilmente alle condizioni logistiche del fine linea e per i cambi formato rapidi e semplici, grazie all'ingresso monofilare. Sono inoltre dotati dell’innovativo sistema Easy-Load che consente l'avanzamento completamente automatizzato delle fustelle di cartone, semplificando le operazioni di caricamento per l'operatore.

| ACW 150-I ERGON | |

|---|---|

| Tipo pacco | Solo vassoio Scatola wrap-around |

| Piste | 1 |

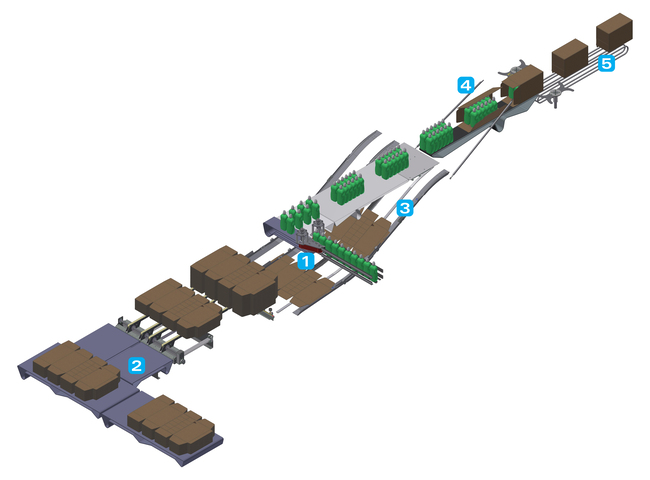

1Un sistema con ingresso ad una fila facilita il corretto incanalamento dei contenitori sfusi su un nastro trasportatore. Il sistema di introduzione prodotto è a ciclo continuo e la formazione del pacco avviene tramite un apposito separatore elettronico. Successivamente, i prodotti sfusi sono traslati dal trasportatore di alimentazione al nastro trasportatore di confezionamento grazie ad un sistema di tipo rotativo.

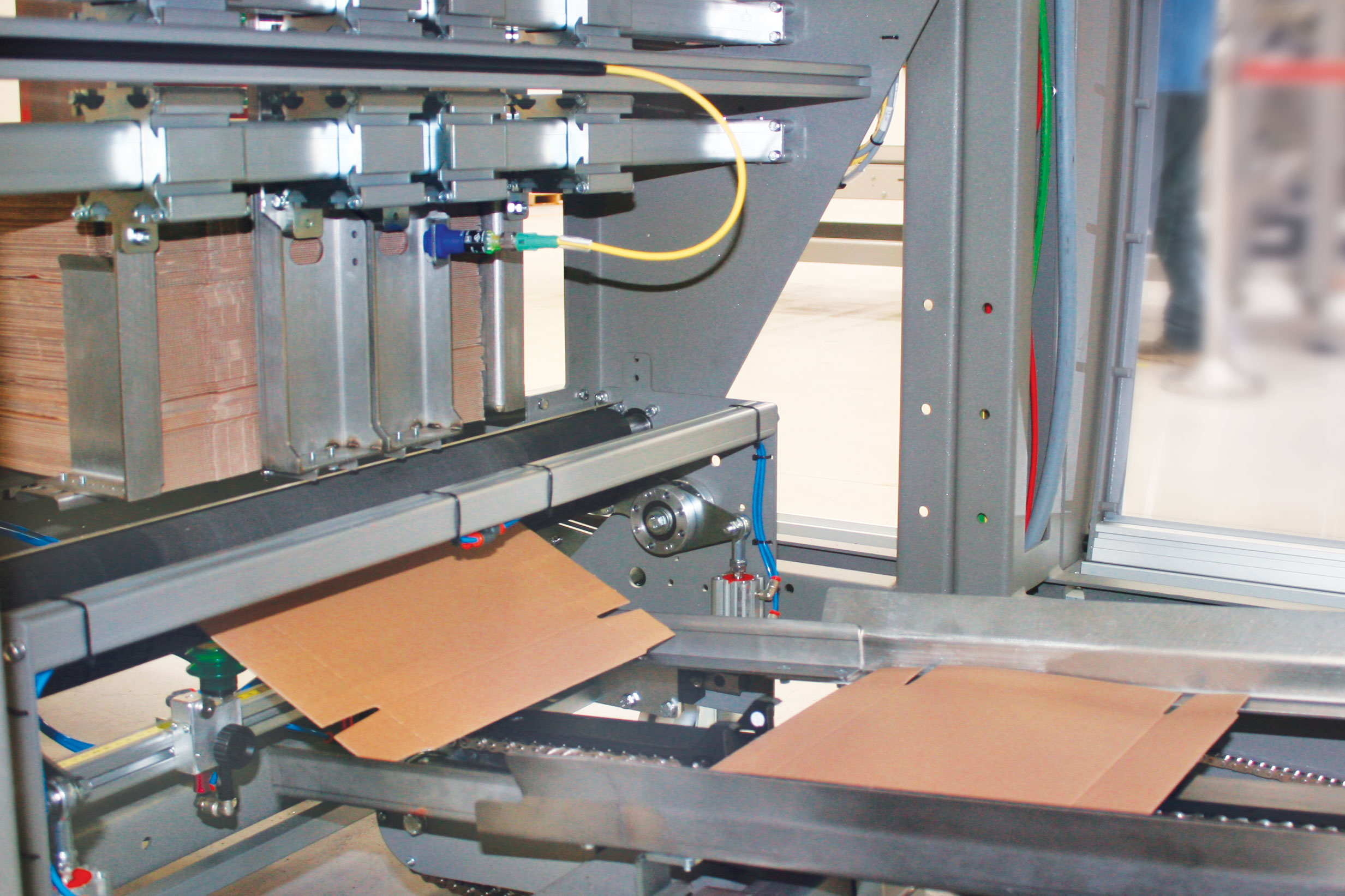

2Sulle macchine ACW 150, il sistema Easy-Load provvede a caricare automaticamente le fustelle di cartone nell'apposito magazzino cartoni. Il nuovo dispositivo di carico è composto da una serie di nastri trasportatori a tappeti motorizzati sui quali l'operatore posiziona con facilità le fustelle di cartone in pile orizzontali uniformi.

3Una fustella di cartone ondulato viene prelevata dal magazzino cartoni da uno sfogliatore rotativo composto da due gruppi di ventose. La fustella percorre la salita cartoni e si posiziona sotto il gruppo di prodotti in arrivo con fronte marcia lato corto. La formatrice scatola/ vassoi opera in modo continuo con sistema wrap-around.

4Nella formatrice scatole/vassoi apposite guide piegano e avvolgono la fustella di cartone intorno ai prodotti in transito. I dispositivi piega-alette piegano prima le alette laterali ed infine quelle superiori/ inferiori, sia del fronte marcia anteriore, sia di quello posteriore. La chiusura tramite colla a caldo assicura un’ottima tenuta del pacco.

5All'uscita della macchina, apposite guide fisse mantengono pressate le pareti della scatola appena realizzata.

- Struttura portante in acciaio sabbiato e verniciato a polveri

- Portelle di protezione scorrevoli in alluminio anodizzato e di forma arrotondata, che consentono di avere tutti i motori (a basso consumo energetico) in posizione esterna rispetto ai gruppi meccanici che azionano. Il sistema di chiusura delle portelle è dotato di un dispositivo di decelerazione, che rallenta la fase finale della corsa accompagnando la portella in maniera armonica.

- Avanzamento completamente automatizzato delle fustelle di cartone (impilate orizzontalmente) sui moduli trasportatori a tappeti motorizzati (ACW 150-I)

- Assenza di motoriduttori e impiego prevalente di motori brushless ICOS dotati di servoazionamento digitale (driver) integrato nel motore

- Sfogliatore cartoni di tipo alternato, dotato di ventose

- Pannello operatore con braccio scorrevole su binario

Soluzione compatta ed ergonomica

Il prodotto sfuso arriva da nastro monofilare; di conseguenza non è necessario prevedere un divisore con l'incanalamento dei prodotti. Questo consente di ridurre sia i costi, sia gli ingombri della linea nastri. Inoltre, la struttura del telaio è ergonomica e funzionale, consentendo dunque all'operatore di svolgere facilmente tutte le attività connesse all'utilizzo e alla manutenzione dell'impianto.Cambio formato facile e veloce

L' ingresso di tipo monofilare offre il vantaggio di poter lavorare diversi tipi di contenitori, di svariate misure senza dover ricorrere ad attrezzature supplementari di nastrini: ne consegue che i cambi formati risultano estremante facili e veloci in quanto non sarà necessario regolare tutte le sponde delle varie file.Preservazione e stabilità del prodotto

La separazione non sollecita il prodotto sfuso in quanto tale operazione avviene mediante cinghie di dosatura; ciò permette di mantenere intatta la forma del contenitore e assicura una migliore stabilità durante la separazione stessa.Flessibilità operativa

Queste confezionatrici permettono di imballare un'ampia gamma di prodotti in un numero elevato di configurazioni differenti, in modo da rispondere efficacemente alle mutevoli esigenze presenti e future dell'utilizzatore finale. Ogni macchina può essere inoltre dotata di attrezzature supplementari che ne incrementano le funzioni base e garantiscono un elevato livello di personalizzazione del pacco finale.Personalizzazione del pacco finale

Questa soluzione consente di creare pacchi con un'ampia superficie da personalizzare. Questo fa sì che il pacco costituisca un vero e proprio strumento marketing e che possa essere utilizzato dai produttori per attrarre l'attenzione del consumatore e al tempo stesso migliorare l'esperienza del cliente, un fattore che gioca un ruolo sempre più importante nelle decisioni di acquisto.Formazione scatole a regola d'arte

Le cartonatrici SMI sono dotate di guide fisse, che all'uscita della macchina mantengono pressate le pareti del pacco. Questo sistema garantisce una quadratura perfetta e duratura delle scatole, a differenza dei sistemi di pressatura con catene rotanti che non sono in grado di fornire lo stesso livello qualitativo.Interfaccia uomo-macchina "user-friendly"

Il pannello di controllo POSYC®, scorrevole su binario per tutta la lunghezza della macchina (a seconda del modello macchina), consente anche agli addetti meno esperti un facile ed efficiente utilizzo della confezionatrice. Ciò è possibile grazie all'interfaccia grafica estremamente intuitiva, allo schermo sensibile al tocco ed alle avanzate funzioni di diagnostica e supporto tecnico in tempo reale presenti sul POSYC®.Contattaci

- SMI S.p.A.

- Indirizzo: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Lunedì - Venerdì: 07:45 - 17:30

Sabato - Domenica: Chiuso

Informativa sulla privacy

PROTEZIONE DATI E PRIVACY

Dal 25 maggio 2018 è pienamente applicabile il Regolamento Europeo 679/2016 (GDPR) che definisce le regole generali per la protezione dei dati personali. Si tratta di un importante traguardo che introduce per tutti i Paesi dell'Unione Europea le medesime regole nel trattamento dei dati personali. Ogni azienda del Gruppo SMI ha promosso e realizzato una seria attività di adeguamento, ripensando assetti o modalità operative/organizzative, sforzandosi di realizzare la protezione dei dati personali “in pratica”. Di seguito alcune delle azioni intraprese per l'applicazione del Regolamento dal 25 maggio 2018 e la nostra politica dei trattamenti dei dati personali.

![]()

Fondamenti di liceità

Per tutte le attività di trattamento il Gruppo SMI ha identificato la base giuridica (consenso, adempimento obblighi contrattuali, interessi vitali della persona interessata o di terzi, obblighi di legge cui è soggetto il titolare, interesse pubblico o esercizio di pubblici poteri, interesse legittimo prevalente del titolare o di terzi cui i dati vengono comunicati).

![]()

Documentazione informativa

Le società del Gruppo SMI hanno arricchito, migliorato e adeguato alle nuove regole le informazioni da dare agli interessati (art. 13 e 14 GDPR).

![]()

Diritti degli interessati (accesso, cancellazione-oblio, limitazione del trattamento, opposizione, portabilità)

Il Gruppo SMI ha adottato misure tecniche e organizzative per favorire l'esercizio dei diritti e il riscontro alle richieste presentate dagli interessati.

![]()

Titolare, responsabile, incaricato del trattamento

Alla luce del nuovo principio di "responsabilizzazione", le aziende del Gruppo SMI hanno ridefinito la propria organizzazione per garantire pro-attivamente l'osservanza del regolamento nella sua interezza. Ha ridefinito i ruoli degli attori del trattamento e dei fornitori di servizi che implicano attività di trattamento su commissione.

![]()

Approccio basato sul rischio del trattamento e Misure di "accountability" di titolari e responsabili (valutazione di impatto, registro dei trattamenti, misure di sicurezza, violazioni dei dati personali)

Attraverso un “Documento di conformità” che incorpora il registro delle attività di trattamento il Gruppo SMI pianifica, attua e dimostra le misure di sicurezza, tecniche e organizzative “adeguate” alle caratteristiche del trattamento e predispone le procedure necessarie per effettuare, ove ne ricorrano i presupposti, la notifica dei “data breach”.

![]()

Trasferimento internazionali di dati

Il Gruppo SMI si impegna a rispettare e fa propri i principi generali e le garanzie per il trasferimento verso Paesi terzi.

Il titolare del trattamento è:

SMI S.p.A.

Sede amministrativa: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

Per informazioni scrivere a: privacy@smigroup.net

Il Regolamento Europeo 679/2016 attribuisce la facoltà di esercitare i diritti esplicitamente previsti per l'interessato.

Alleghiamo il testo integrale degli artt. 15; 16; 17; 18; 20; 21; 77 del Regolamento medesimo che descrivono il contenuto e le modalità di esercizio di tali diritti.

Al fine di consentirle di esercitare tali diritti, le chiediamo di inviare il modulo di richiesta debitamente compilato all'indirizzo del Titolare.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

.jpg)