Multipack packers with top pad with in-line infeed

TPP ERGON Series

TPP 300 ERGON - Multipack packers with top pad up to 300 ppm

The automatic packers from the TPP ERGON (acronym for Top Pad Packer) range represent the cutting-edge plastic-free solution for packing several types of cans in multipack through the application of a cardboard pad positioned in the upper part of the pack.

These packers, realizing packs in 2x2 and 2x3, can reach an output up to 300 packs/minute and are suitable for those beverage manufacturers who want to actively follow a circular economy pattern and at the same time put on the market packs with a high visual impact.

This solution combines operational flexibility and the capability of processing different types of containers in several configurations with high technology, based on the improvement of a proven series that SMI has been producing for years (the MP ERGON series).

| TPP 300 ERGON | |

|---|---|

| Speed (PPM) | 300 |

| Lanes | 1 |

- Machine bearing frame made of sand-blasted and powder-painted steel

- Sliding protection doors in anodised aluminium featuring a rounded shape which let all the motors (featuring low energy consumption) be placed externally if compared to the mechanical groups they activate. The closing system of doors is equipped with a slow-down device, which accompanies the door smoothly in its final phase of closure

- Absence of gearboxes and prevailing employment of ICOS brushless motors equipped with digital servo-driver integrated into the motor

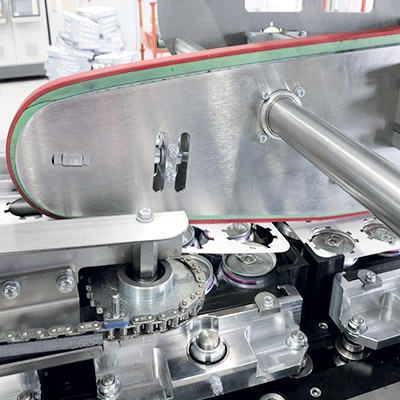

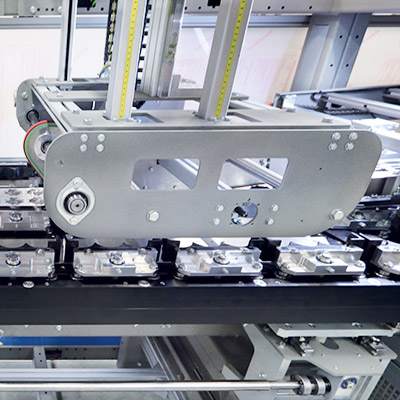

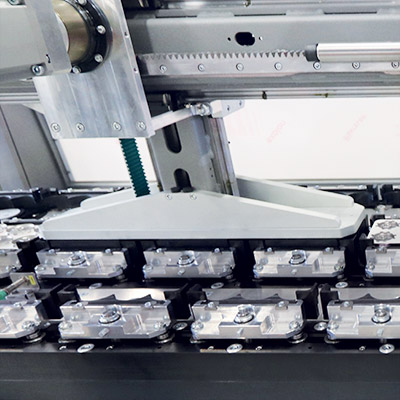

- Continuous motion product grouping device, with electronically synchronized fingers made of plastic material

- For life lubricated bearings

- Cardboard magazine situated above the infeed conveyor, adjustable according to the blank size

- Alternate motion cardboard blank picker, equipped with suckers

- Interactive touchscreen display with intuitive graphics

Operational flexibility

These machines can package a wide range of products in several pack collations, so as to effectively meet the end user's current and future requirements. Moreover, each machine can be equipped with additional devices, which increase its basic functions and ensure a high level of customization of the final package.Environmentally sustainable solution

The packs generated by the TPP packer are made of renewable, biodegradable and fully recyclable top cardboard pad. This represents a valid alternative to packs in shrink film and offers the advantage of not requiring a shrinking process compared to them, with benefits in terms of consumption and carbon footprint.Material saving

The pack is composed of a top pad only. This results in significant saving in terms of material, and, all of this, without compromising on the pack stability, functionality and aesthetics.Glue-free packs

The new multipacks do not require the use of glue, as they are kept stable by the punched and folded cardboard topper. This enhances the environmental sustainability of the pack.Customized packs

This solution enables to manufacture packs with a wide surface to customize. This means that this pack acts as a real marketing tool and can be used by manufacturers to draw the consumer’s attention and at the same time to enhance the customer experience, a factor that plays an increasingly important role in the buying decisions."User-friendly" man-machine interface

The POSYC® control panel, sliding on a boom running the whole length the machine, is very easy to use, thanks to the intuitive interface, the touch screen and the diagnosis functions and real-time technical support on the POSYC®.Images are for illustrative purposes and data are not binding, as they have to be confirmed by SMI according to the machine user's production conditions and technical specifications.

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA