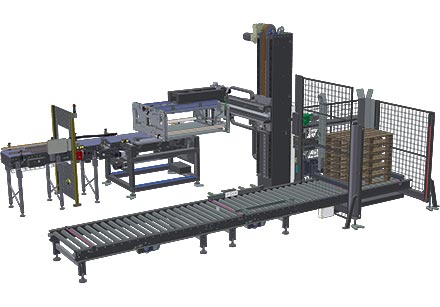

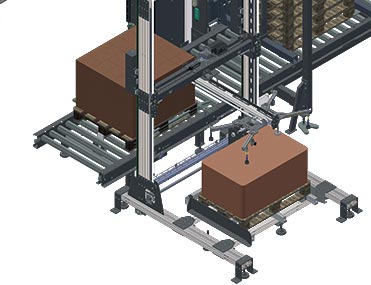

Automatic palletizing systems with 90° infeed

APS 1540 ERGON Series

APS 1540 - Palletizer

The APS 1540 is a single-column system based on two Cartesian axes motion for the palletization of cases, bundles, trays and other commonly used packs, composed of several modules configurable in a customized manner depending on the logistical conditions of the end-of-the line and the palletizing requirements.

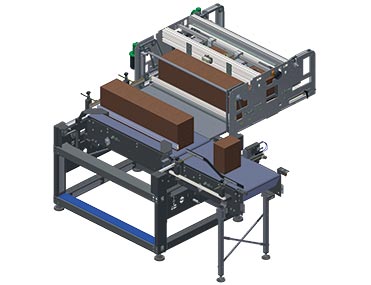

The core of the APS ERGON system is the module of the vertical axis, a fixed column (liftable by crane only), along which the horizontal axis of operation made up by the beam runs on recirculating-sphere guides.

The horizontal beam, along which the picking head-holding arm runs on recirculating-sphere guides, can be combined with:

- 90° product infeed module and layer pre-composition system;

- Pallet module with maximum load capacity of 300 kg (max. 10 pallets with maximum height of 150 mm and maximum load capacity of 30 kg/pallet) including conveyor and empty pallet magazine (pallet modules with higher load capacity are available as optionals);

- Pad-inserting module (optional), composed of pad magazine and the pad-inserting unit with controlled axes;

- Protection bars.

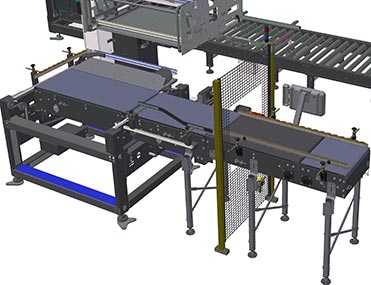

In the pallet infeed, the product infeed conveyor forms the row, together with the translation system that with a one-way movement contributes to the formation of the layer.

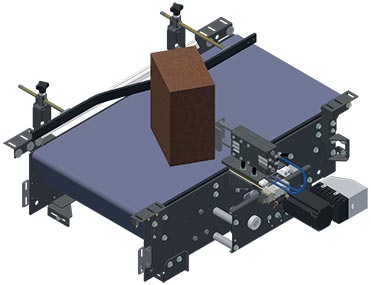

The picking head picks the pack layers from a conveyor belt at operator's height. The vertical movements of the beam and the horizontal movements of the head-holding arm are activated by brushless motors, ensuring perfect trajectories during all palletizing phases.

The APS 1540 handles 800x1200 mm and 1000x1200 mm Euro pallets (other formats are available upon request).

All the operations are controlled by a user-friendly system for the machine automation and control, enabling an easy and efficient use of the palletizing system by the operator.

| APS 1540 | |

|---|---|

| Speed (PPM) | 40 |

Compact and ergonomic structure

The compact and ergonomic structure ensures great space saving inside the bottling line and allows the operator to easily and safely carry out all the activities related to the use, cleaning and maintenance of the plant.Operational flexibility

The use of innovative, smart and customized technical solutions ensures great advantages in terms of operational flexibility and economic competitiveness of the processes. In particular, SMI palletizers from the APS series enable to create several palletizing patterns according to the specific requirements of the customer and offer wide customization possibilities in order to adapt to the changeover, product change and/or plant layout requirements.Quick and precise movements

The machine axes are controlled by brushless motors that ensure highly dynamic, harmonic and precise movements.Low operating costs and reduced maintenance

The TCO (Total Cost of Ownership) is optimized thanks to low operating and maintenance costs.Eco-friendliness

SMI palletizers from the APS series are an eco-friendly solution, thanks to the use of ICOS motors with built-in servo-driver, able to simplify the machine wiring and ensure greater energy efficiency, low noise level and reduced component wear.Single-entry infeed with 90° layer-forming system

Single-entry infeed with 90° layer-forming system equipped with: 1 rubberized cadencing belt, 1 product infeed belt, in order to form the row and 1 one-way translation system that contributes to forming the layer into the basket. The layer-forming system is equipped with energy-efficient motors. Designed in accordance with FCR (Full Cost Reduction) methodologies, it is tested and supplied to the client fully assembled and cabled. Start-up time is really short, since it consists in connecting the connectored cable of signals and power of sercos fieldbus to the central module of APS palletizing system. The ergonomic and functional structure of the frame allows the operator to easily carry out all the operations related to the use and maintenance of the plant.Row transfer device

The row transfer process is managed by a motorized bar. After a row is formed, it gets pushed straight away into the loading head (basket). The system is also equipped with a ”dead” plate (buffer), which enables to continue row push-in operations even when the head is not yet in the loading position.Pack rotation device (optional)

This optional system allows to turn packs being fed to the palletizer by means of a contrast cylinder. If packs are getting to the machine with the short side leading, a second optional cylinder is available to ease the rotation process.Empy pallets feeding system

The APS ERGON palletizer is equipped with an empty pallet feeding system composed of roller conveyors. Maximum storage capacity: 300 kg (pallet modules with higher capacity are available as optionals) and/or maximum total height of 1800 mm. Designed in accordance with FCR (Full Cost Reduction) methodologies, this system is tested and supplied to the client fully assembled and cabled.Pad feeding system (optional)

The pad-inserting module is a pad feeding system adjustable in accordance with the size of the interlayer pad. Suction-cup gripping system from 4 up to 8 adjustable points to ensure the accurate lifting of any kind of interlayer. The interlayer pad automatic loading is available as optional and allows to load the pallet of interlayer pads without stopping the machine (through the addition of one station for loading pallets of interlayer pads and one station for unloading empty pallets)Pallet roller conveyor

Frame in painted steel and rollers with 76 mm ø 150 mm pitch, motorised through a 5/8 inch chain. Electronically reversible central motorization. The system is tested in SMI factory and is supplied to the client fully assembled and cabled. Available in different lengths: 1500 mm, 2000 mm, 2500 mm and 3000 mm.Images are for illustrative purposes and data are not binding, as they have to be confirmed by SMI according to the machine user's production conditions and technical specifications.

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA