Upgrades

ZF010413 - Panel de enfriamiento del horno

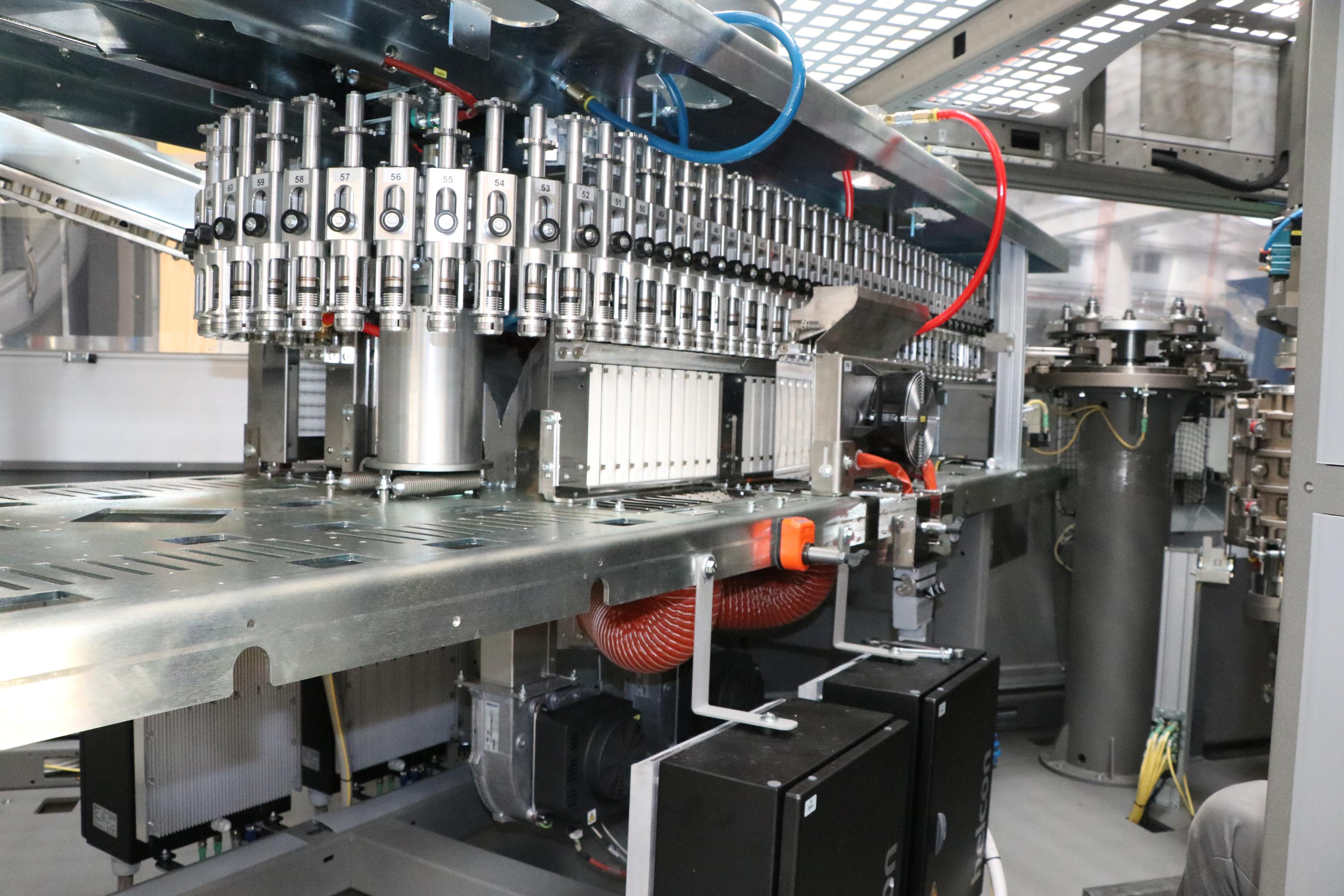

Máquinas: EBSK - EBS E - EBSHC

Ventajas: Incremento del rendimiento - Ahorro energético

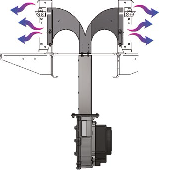

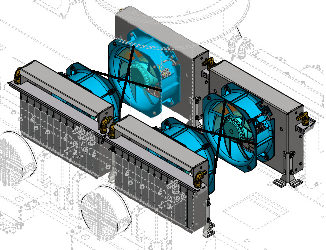

La actualización consiste en la instalación de un nuevo ventilador centrífugo reforzado junto con un nuevo conducto de aire, según el número de paneles instalados.

Ha sido diseñado específicamente para asegurar un proceso de enfriamiento eficiente incluso a altas temperaturas, manteniendo así a lo largo del tiempo un perfil de calentamiento uniforme y constante de las preformas.

Esto se traduce en beneficios en el enfriamiento del cuello de la preforma, un factor que desempeña un papel especialmente relevante en el ciclo de producción. De hecho, permite mantener estable la temperatura del cuello de la preforma, ya que posibilita reducir la temperatura del horno hasta 10° en comparación con los ventiladores estándar.

Gracias a la nueva posición del ventilador, situado en la parte inferior de la máquina, y al doble canal de ventilación, se instala una solución ideal para una circulación de aire eficiente a temperaturas más bajas dentro de los paneles.

Con este sistema, además, es posible desactivar el enfriamiento de las preformas mediante el sistema vortex, reduciendo así el consumo de aire.

Requisitos mínimos

Adecuado para todas las sopladoras de la serie EBS equipadas con ventiladores de enfriamiento instalados directamente en los paneles.

Ventajas

- Incremento de la eficiencia productiva

- Mejora en el calentamiento de las preformas

- Reducción de la temperatura del horno hasta 10°

- Disminución del consumo de aire al desactivar el sistema de soplado vortex

- Eliminación de errores en la transferencia horno-molde

Contacts

Contáctanos

- SMI S.p.A.

- Dirección: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Lunes - Viernes: 07:45 - 17:30

Sábado - Domingo: Cerrado

Newsletter

© SMI S.p.A. 2026

Nota informativa sobre el tratamiento de tus datos personales - Legal notice

Nota informativa sobre el tratamiento de tus datos personales

PROTECCION DATOS Y PRIVACY

A partir del 25 de mayo de 2018 es totalmente aplicable el Reglamento Europeo 679/2016 (GDPR) que define las normas generales para la protección de datos personales. Este es un hito importante que introduce las mismas reglas para el procesamiento de datos personales para todos los países de la UE. Todas las empresas del Grupo SMI han promovido e implementado una actividad de ajuste seria, repensando estructuras o métodos operativos/organizativos, esforzándose por lograr la protección de datos personales "en la práctica". Las siguientes son algunas de las acciones tomadas para aplicar el Reglamento a partir del 25 de mayo de 2018 y nuestra política de procesamiento de datos personales.

![]()

Fundamentos de legalidad

Para todas las actividades de tratamiento, el Grupo SMI ha identificado la base legal (consentimiento, cumplimiento de obligaciones contractuales, intereses vitales del interesado o terceros, obligaciones legales a las que está sujeto el propietario, interés público o el ejercicio de la autoridad pública, el interés legítimo prevaleciente del titular o de terceros a quienes se comunican los datos).

![]()

Documentación informativa

Las empresas del Grupo SMI han enriquecido, mejorado y adaptado a las nuevas normas la información que se debe proporcionar a las partes interesadas (artículos 13 y 14 del RGPD).

![]()

Derechos de las partes interesadas (acceso, cancelación-olvido, limitación de procesamiento, oposición, portabilidad)

El Grupo SMI ha adoptado medidas técnicas y organizativas para promover el ejercicio de los derechos y la respuesta a las solicitudes de las partes interesadas.

![]()

Titular, responsable, encargado del tratamiento

A la luz del nuevo principio de "empoderamiento", las empresas del Grupo SMI han redefinido su organización para garantizar el cumplimiento proactivo de la regulación en su totalidad. Ha redefinido los roles de los actores de tratamiento y proveedores de servicios que involucran actividades de procesamiento basadas en comisiones.

![]()

Enfoque basado en el riesgo para el tratamiento y las medidas de " accountability" de los propietarios y gerentes (evaluación de impacto, registro de tratamiento, medidas de seguridad, violaciones de datos personales)

A través de un "Documento de Cumplimiento" que incorpora el registro de actividades de tratamiento, el Grupo SMI planifica, implementa y demuestra las medidas de seguridad, técnicas y organizativas "adecuadas" a las características del tratamiento y prepara los procedimientos necesarios para llevar a cabo, cuando sea necesario supuestos, la notificación del "data breach".

![]()

Transferencia internacional de datos

El Grupo SMI se compromete a respetar y adoptar los principios y garantías generales para la transferencia a terceros países.

El titular del tratamiento de datos es:

SMI S.p.A.

Oficina administrativa: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

Para información escriba a: privacy@smigroup.net

El Reglamento Europeo 679/2016 otorga el derecho a ejercer los derechos expresamente previstos para la persona interesada.

Adjuntamos el texto completo de los artículos. 15; 16; 17; 18; 20; 21; 77 del mismo Reglamento que describe el contenido y los métodos para ejercer estos derechos.

Para permitirle ejercer estos derechos, le pedimos que envíe el formulario de solicitud debidamente completado a la dirección del Propietario.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA