Upgrades

ZF010041 - Groupe fond du moule et came de manutention

Machines:

Avantages: Augmentation efficacité - Actualisation technologique

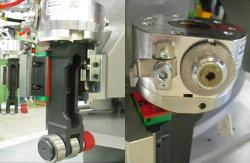

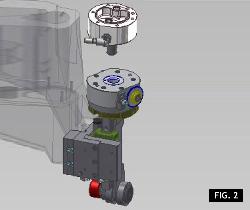

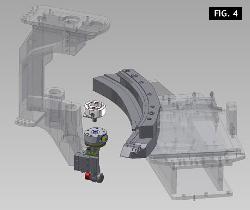

Cette mise à niveau (upgrade) est une nouvelle solution technique développée pour améliorer la performance des souffleuses SMIFORM de deuxième et troisième série, grâce à un design complètement révisé du groupe de fixage et manutention du fond du moule (voir figures).

Les nouveautés introduites par le nouveau système entraînent un changement intégral de la structure du groupe, tout en exploitant ses composants le mieux que possible.

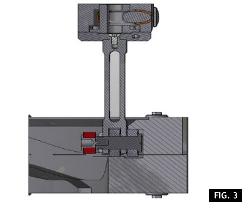

Notamment, le déplacement du roulement de soulèvement en ligne avec le centre du fond du moule a permis l'élimination presque totale des torsions mécaniques sur le chariot, qui peut donc fonctionner de manière optimale.

Cette nouveauté augmente la durée du chariot et réduit la nécessité d'intervention d'entretien. (voir figures).

Cette application autorise des mouvements fluides et précis, permettant d'optimiser la synchronisation entre les mouvements d'ouverture/fermeture du moule et la descente du fond du moule; par conséquent, l'étireusesouffleuse assure un rendement meilleur et plus de fiabilité.

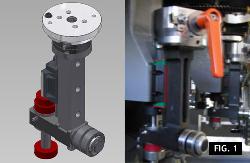

Une autre application importante concernant le groupe support fond du moule est le nouveau système de fixage: on est passé d'une version pneumatique à une mécanique, plus solide et précise.

L'introduction du pivot de fixage, de la roue dentée et de la fermeture par le biais d'une vis a permis de réduire considérablement le jeu entre le fond du moule et son support, tout en facilitant le centrage du moule pendant les opérations de changement de format.

Cela autorise une considérable économie de temps pour les machines où l'opération de changement de format est fréquente.

La nouvelle application apporte même des avantages esthétiques sur le produit fini, grâce à la réduction des lignes de jonction entre le fond et le moule; en plus, la durée des composants mécaniques du groupe, des moules et du fond du moule en résulte augmentée.

La réduction des jeux autorise même une considérable économie des temps de maintenance, grâce à l’élimination des composants pneumatiques du groupe de fixage et à la réduction du poids de l'entretoise de support, ce qui réduit les frictions (voir figures 1 et 3).

La fourniture comprendra l'équipement nécessaire pour modifier les supports des fonds du moule dans la machine et les fonds du moule de chaque format, de même qu'une nouvelle came de manutention optimisée.

Le profil de cette came a été développé selon les plus modernes technologies de simulation, grâce à la collaboration avec des instituts universitaires spécialisés, afin de prédisposer un projet optimal, tout en minimisant les chocs et l'usure des organes de mouvement.

NOTE IMPORTANTE: cet “upgrade” inclut les systèmes décrits ci-dessus et la modification d'un format; pour tout format supplémentaire, il faut envoyer une demande spécifique.

Domaines d'application: à partir de la série équipée de système pneumatique.

Avantages

- Mouvements plus précis;

- Meilleure durée et coûts d'entretien réduits;

- Meilleure jonction entre le fond et le moule;

- Simplification du changement de format et réduction des temps de centrage du fond du moule.

Contacts

Contactez-nous

- SMI S.p.A.

- Adresse: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Lundi - Vendredi: 07:45 - 17:30

Samedi - Dimanche: Fermé

Informations sur la privacy

PROTECTION DONNEES ET PRIVACY

Depuis le 25 mai 2018 le Règlement Européen 679/2016 (RGPD) est entré pleinement en application, définissant les règles générales pour la protection des données personnelles. Il s'agit d'une étape importante, qui fixe les mêmes règles pour le traitement des données personnelles pour tous les Pays de l'Union Européenne. Chaque société du Groupe SMI a développé une série de procédures d'adaptation aux nouvelles règles, tout en révisant les structures ou les modalités opérationnelles pour mettre en pratique les règles de protection des données personnelles. Voici quelques initiatives pour l'application du Règlement à partir du 25 mai 2018 et notre procédure de traitement des données personnelles.

![]()

Licéité du traitement

Le Groupe SMI a établi la base juridique pour le traitement des données personnelles (consentement, exécution des obligations contractuelles, intérêts vitaux des personnes concernées ou de tiers, obligations auxquelles est soumis le titulaire, intérêt public ou exercice de l'autorité publique, intérêt légitime supérieur du titulaire ou de tiers auxquels les données sont communiqueés).

![]()

Dossier d'information

Les sociétés du Groupe SMI ont enrichi, amélioré et adapté aux nouvelles règles le dossier d'information à fournir aux personnes concernées (articles 13 et 14 RGPD).

![]()

Droits des personnes concernées (accès, oubli ou effacement, limitation du traitement, opposition, portabilité)

Le Groupe SMI a adopté des mesures techniques et organisationnelles pour favoriser l'exercice des droits et la réponse aux demandes envoyées par les personnes concernées.

![]()

Responsable du traitement

Sur la base du nouveau principe de "responsabilité", les sociétés du Groupe SMI ont redéfini leur organisation pour garantir le respect pro-actif du règlement. On a redéfini le rôle du responsable du traitement et des fournisseurs de services, dont l'activité implique le traitement des données personnelles.

![]()

Risque du traitement et mesures de “responsabilité” adoptées par les responsables du traitement (évaluation d'impact, registre des activités de traitement, mesures de sécurité, violation des données personnelles)

Grâce à un “Document de conformité” incluant le registre des activités de traitement, le Groupe SMI planifie, met en oeuvre et démontre toutes les mesures de sécurité, techniques et organisationnelles, adaptées aux caractéristiques du traitement et prévoit les mesures nécessaires pour notifier la violation des données.

![]()

Transfert international des données

Le Groupe SMI s'engage à respecter les principes généraux et les garanties pour le transfert des données vers des Pays Tiers.

Le responsable du traitement est:

SMI S.p.A.

Bureaux administratifs: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

Pour toute information, écrivez à: privacy@smigroup.net

Le Règlement Européen 679/2016 autorise à l'exercice des droits expressément prévus pour les personnes concernées.

Veuillez trouver ci-joint le texte intégral des articles 15; 16; 17; 18; 20; 21; 77 du Règlement, qui définissent les droits et les modalités d'exercice.

Afin d'exercer vos droits, veuillez envoyer le formulaire dûment rempli à l'adresse du Responsable du traitement.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA