Upgrades

In addition to new-manufactured models, also machines already installed at customers' facilities can be equipped with latest technologies and applications through a set of upgrade solutions implemented by qualified service engineers of SMI after-sales service; that option allows to progressively enhance SMI machines' efficiency and flexibility all along their life cycle.

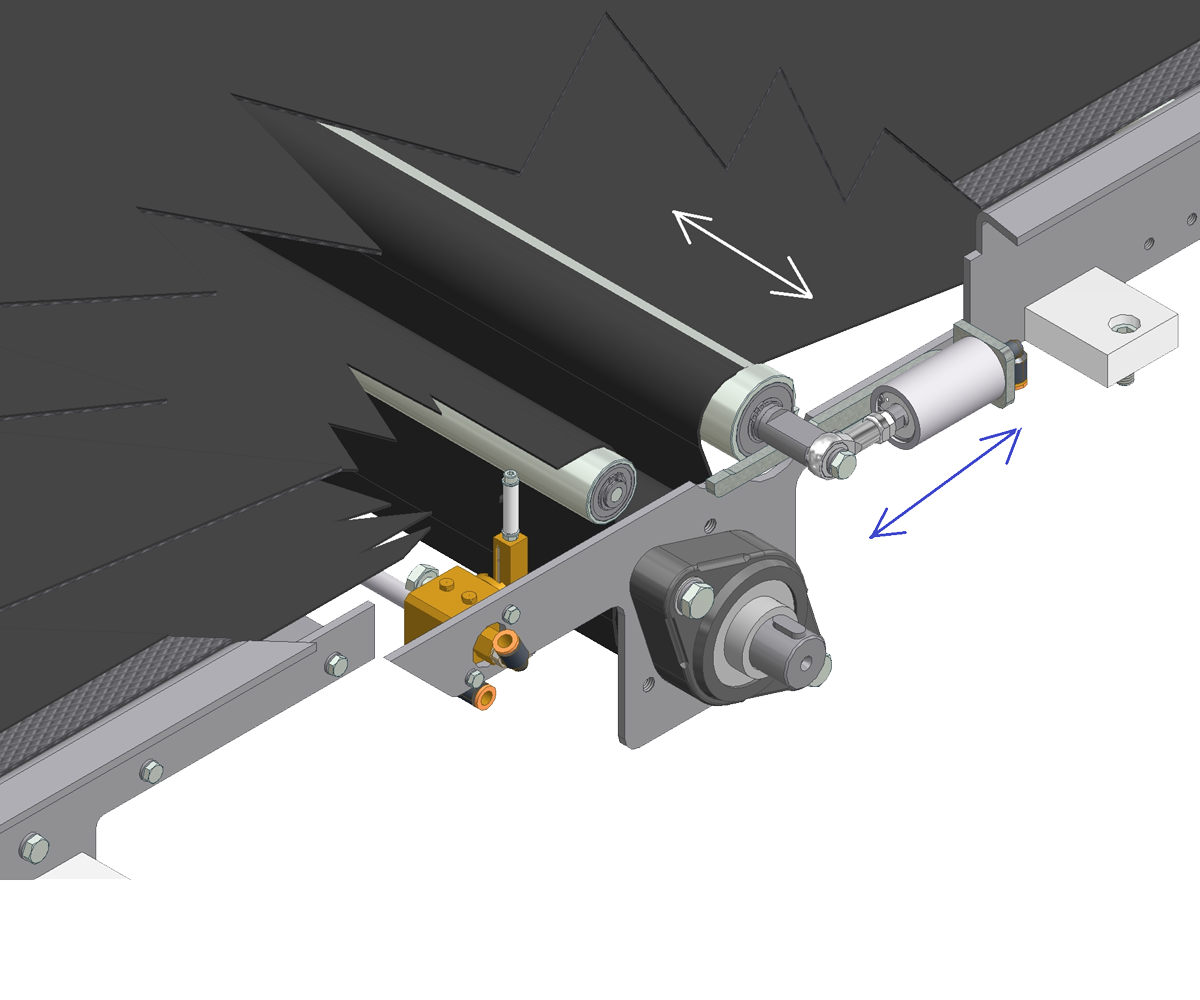

ZF010011 - Belt automatic centering systems

Machines: SK

Benefits: Efficiency increase - Technology update

The upgrade consists in the replacement of the belt groups with state-of-the-art groups featuring a new design in the driving and centering system. This is part ...

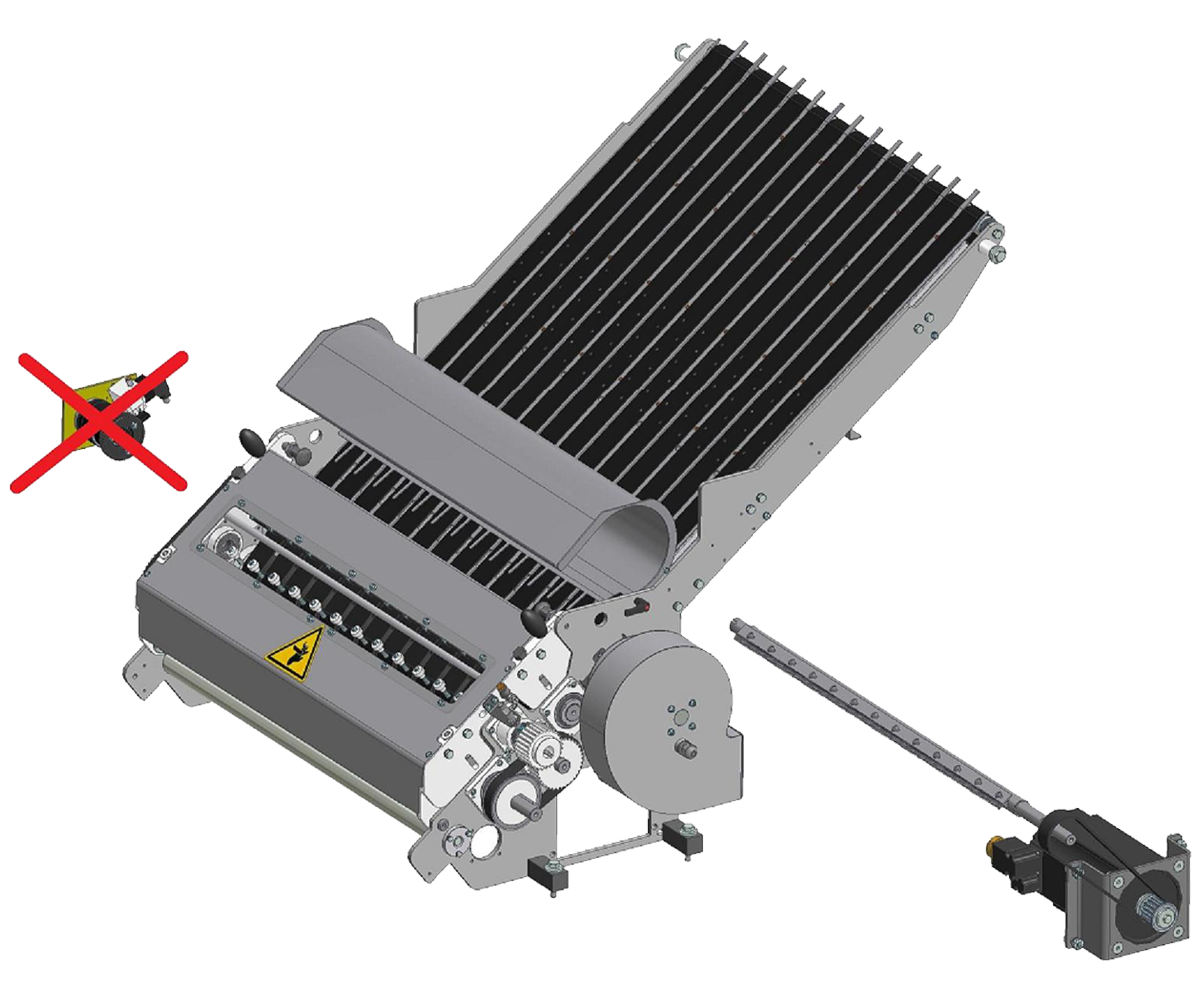

ZF010007/8 - Knife group with motorized blade for single and double lane SK shrinkwrappers

Machines: SK

Benefits: Efficiency increase - Technology update

The upgrade consists in the replacement of the entire cutting unit with a new, more efficient model, easier to maintain. This is part of a series ...

ZF010009/10 - Knife group with motorized blade for single and double lane SK shrinkwrappers, including tension rolls and servo-driven reel holder

Machines: SK

Benefits: Efficiency increase - Energy saving - Technology update - Cost cutting

The upgrade consists in the replacement of the entire cutting, tensioning and unwinding unit with a new, more efficient model, easier to maintain. This is part ...

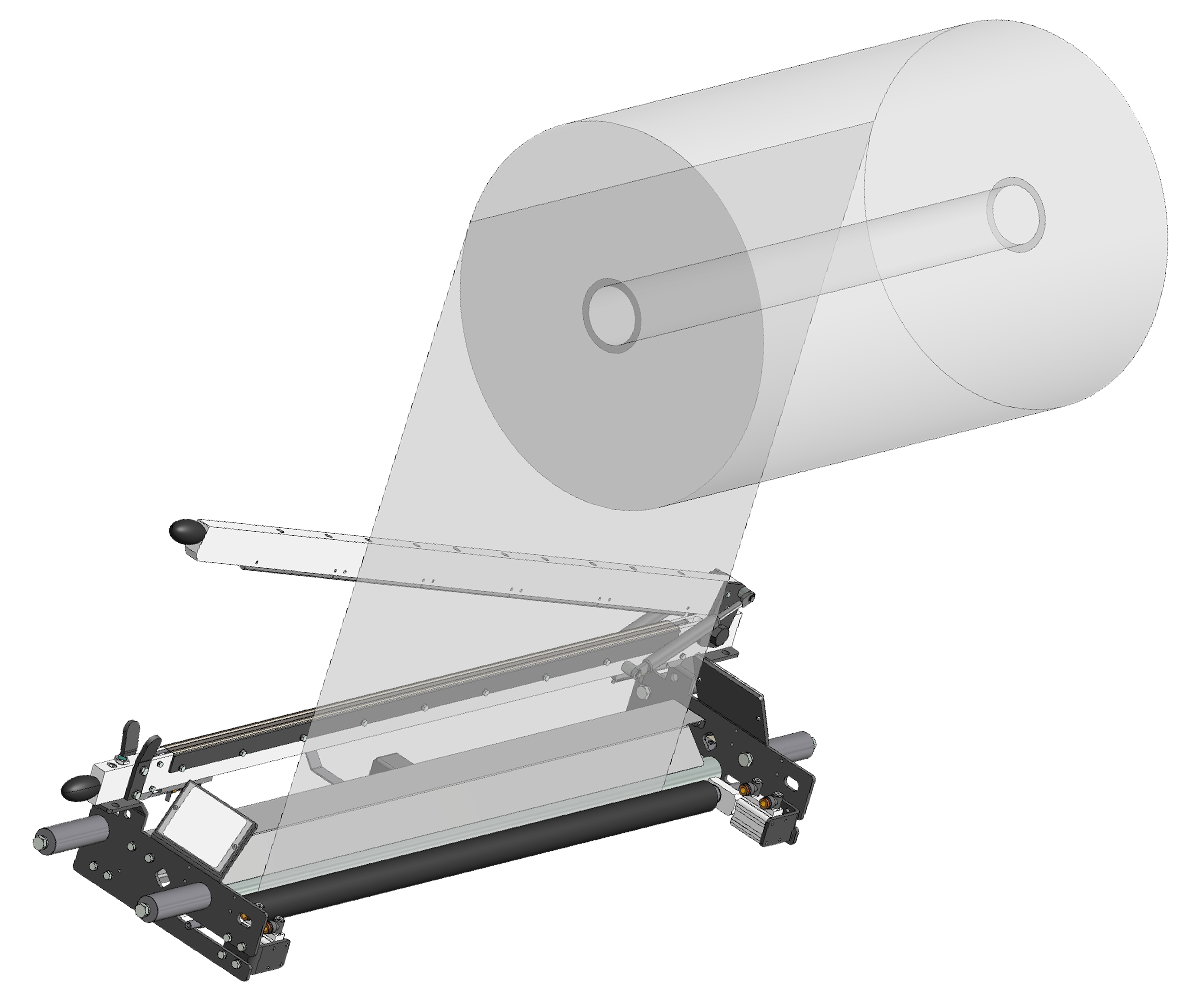

ZF010014 - Film-blocking roll for reel change

Machines: SK

Benefits: Efficiency increase - Technology update

The upgrade integrates the manual welder with a roll that keeps the film during the sealing and the reel changing. This is part of a series ...

ZF010012 - 3000 System Posyc & Marts upgrade

Benefits: Efficiency increase - Process automation - Technology update

The retrofit includes the whole upgrade of the machine control system, both for the hardware and for the software components. This is part of a series ...

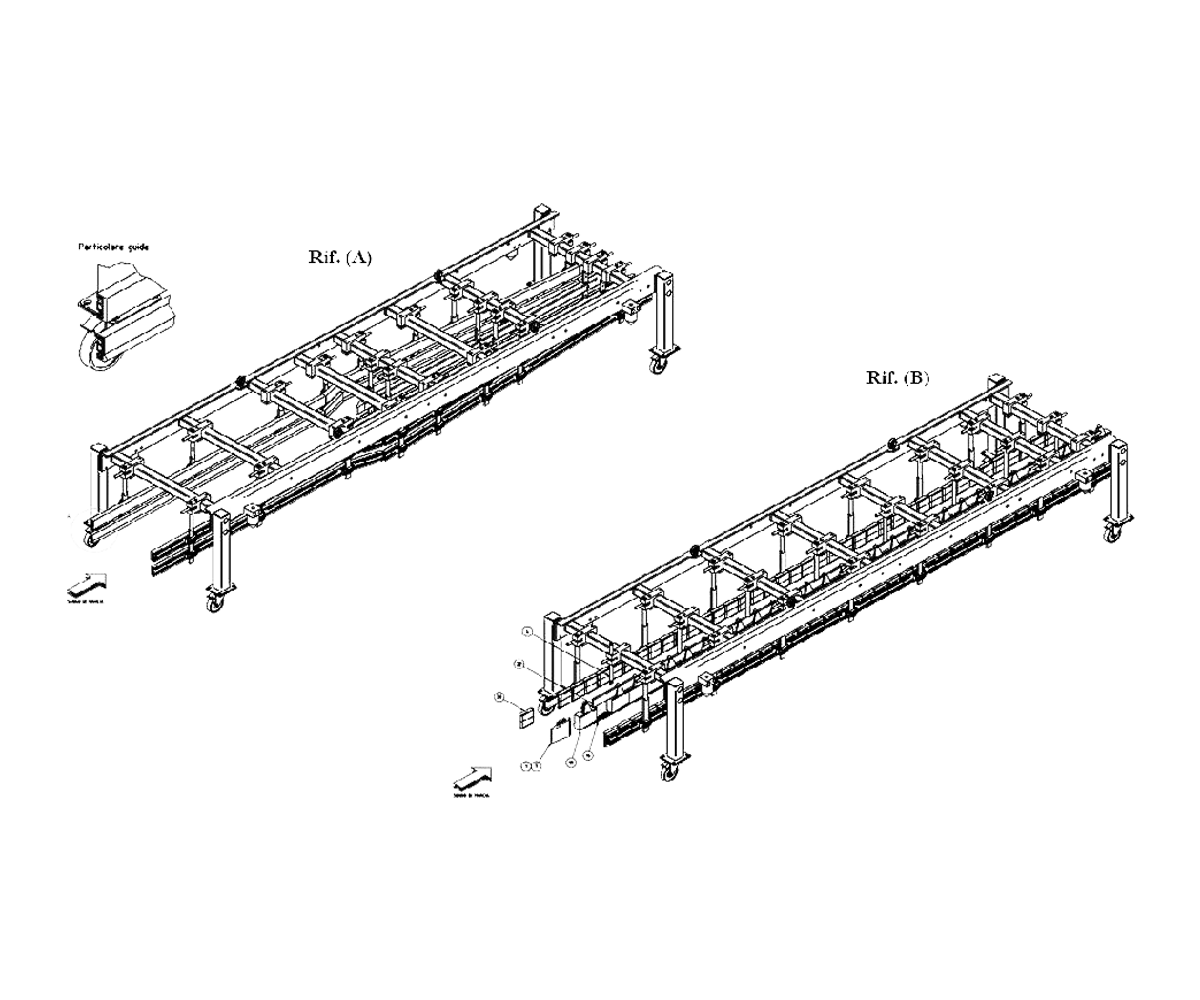

ZF010015 - Group for a quick change of the product guides in the machine infeed area

Machines: SK

Benefits: Efficiency increase - Technology update

This upgrade consists in supplying the necessary equipment for a quick change of the product guides on the machine infeed conveyor. The equipment includes a frame ...

ZF010016 - POSYC holding system from top, including housing aluminum profile.

Benefits: Efficiency increase - Technology update

The upgrade includes the installation of the operator panel on a smooth guide at the top of the machine frame without ground support. This is part ...

ZF010017/18 - Motorized product stabilizer

Benefits: Efficiency increase - Technology update

The upgrade consists in implementing a device called “Motorized product stabilizer”. This is part of a series of new solutions studied by SMI in order to ...

ZF010019 - Upgrade of the backup power supply from Lever or Ultra system to stabilized power supply Sitop + battery

Benefits: Technology update

The upgrade of the backup power supply consists in the replacement of the Ultra or Lever System and the 24V power supplier with a stabilized ...

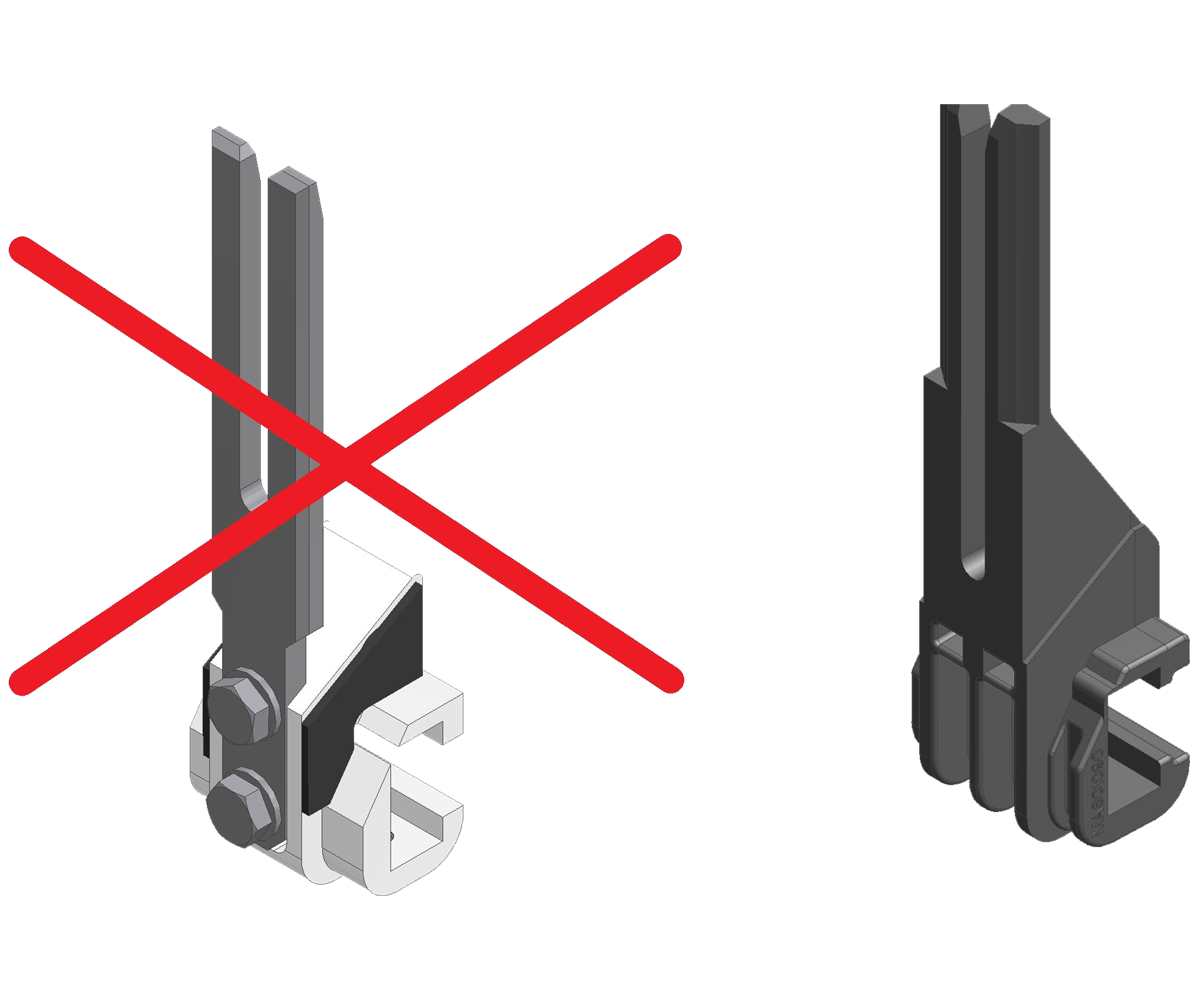

ZF010025 - Replacement of the Al-Steel fingers with new generation plastic fingers.

Machines: SK

Benefits: Efficiency increase - Technology update

This upgrade consists in supplying the whole series of product separation pins made of plastic (a unique piece). This is part of a series of retrofitting ...

ZF010066/88 - Control system upgrade to 3000 Version

Benefits: Environment care - Energy saving - Process automation - Technology update

The retrofitting consists in the whole upgrade of the machine control system, as far as the hardware and the software components are concerned. This is part ...

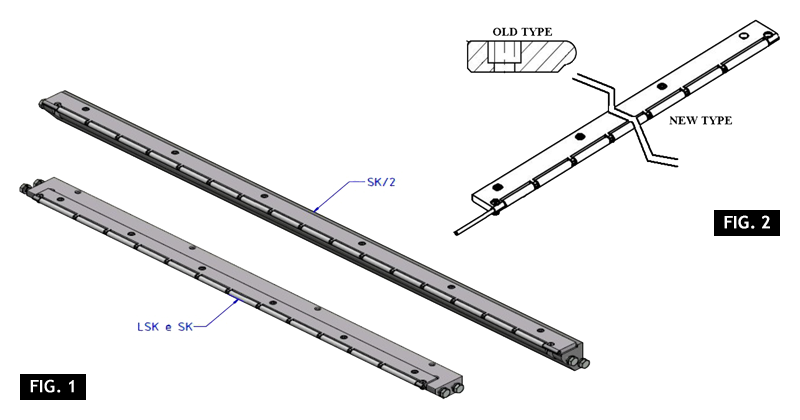

ZF010102 - Upgrade of splitting film system with new features

Machines: SK

Benefits: Efficiency increase - Technology update

This upgrade consists in the replacement of the splitting sensor unit with a new type as per the new machine. With the new feature, the centering ...

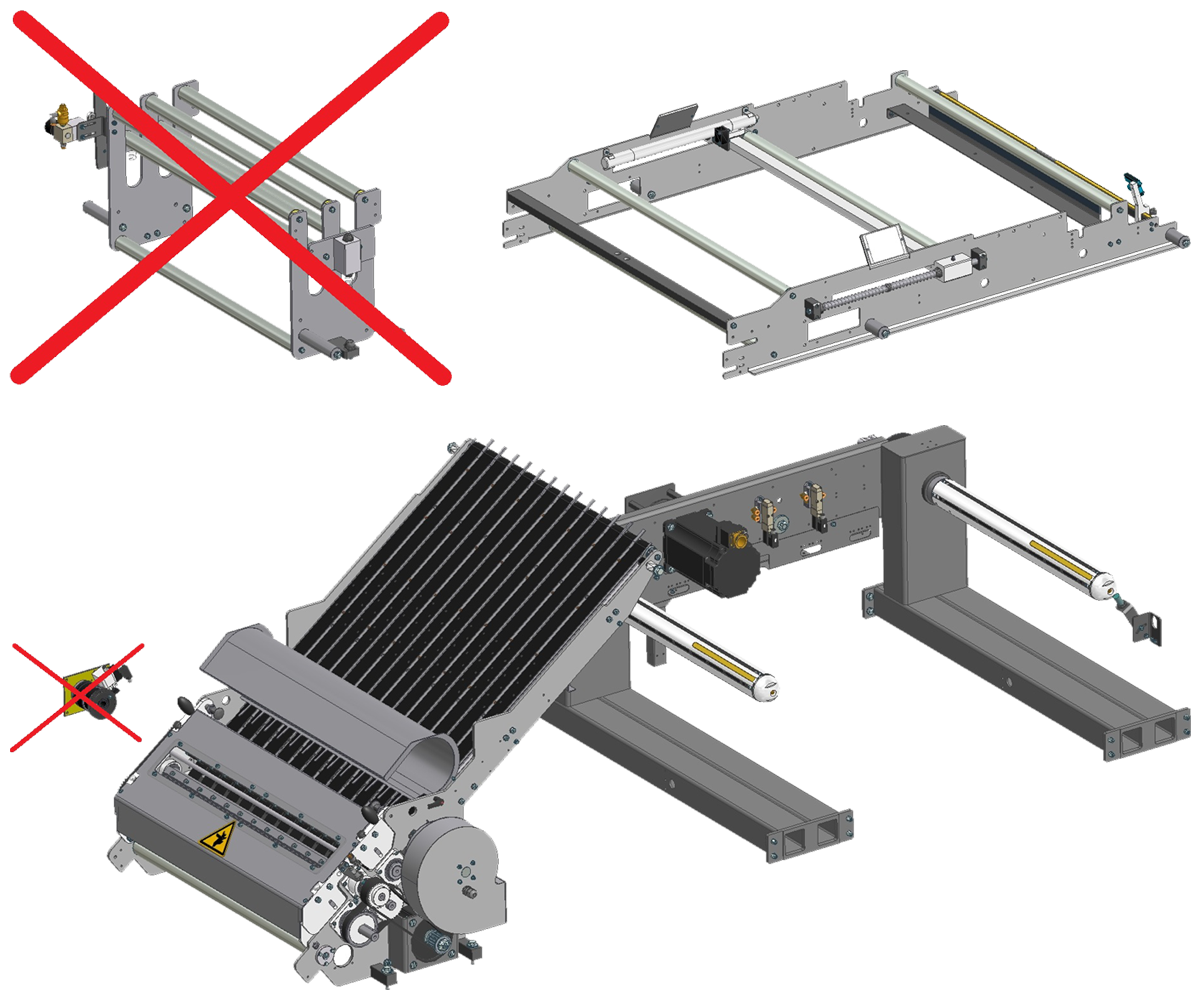

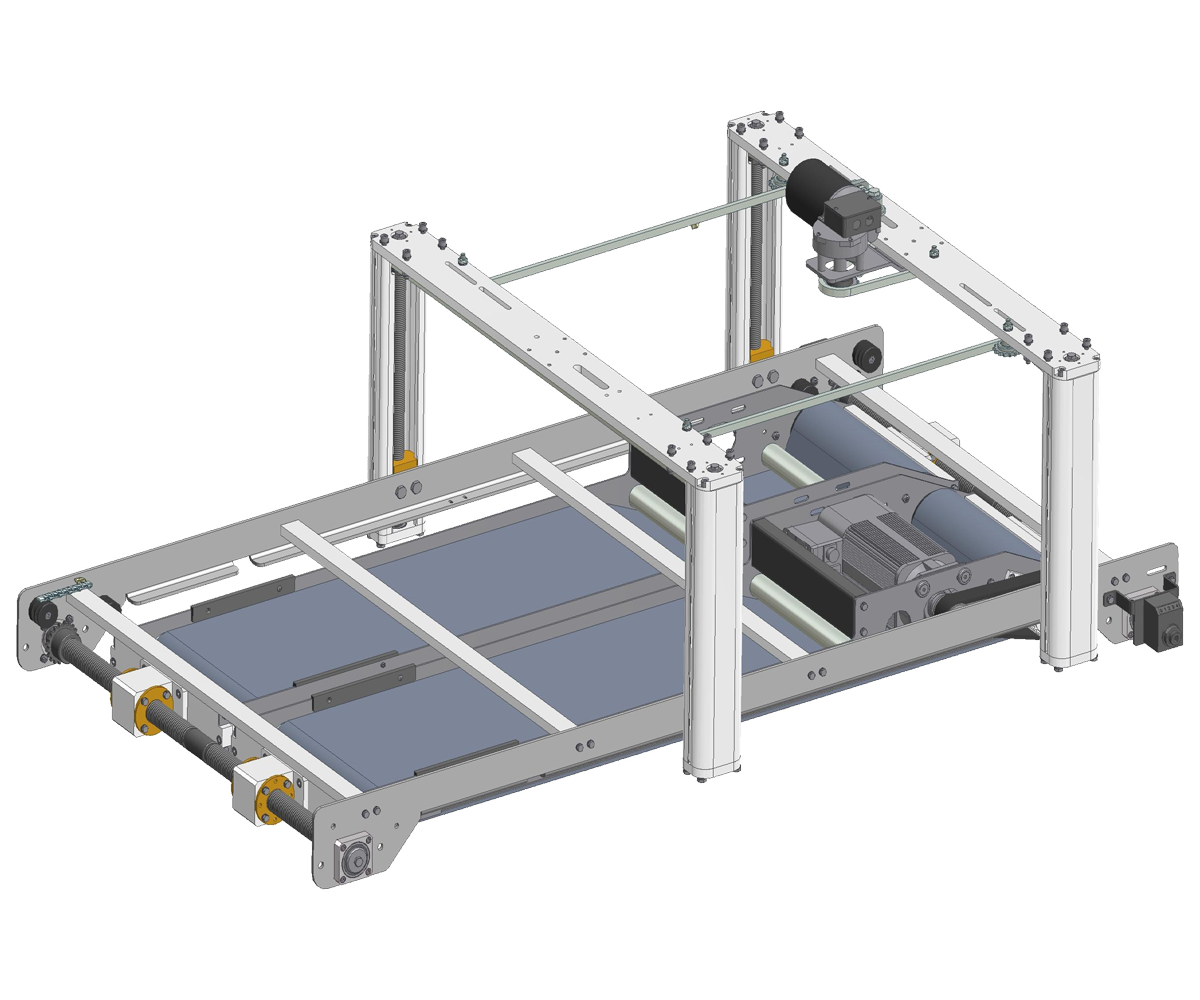

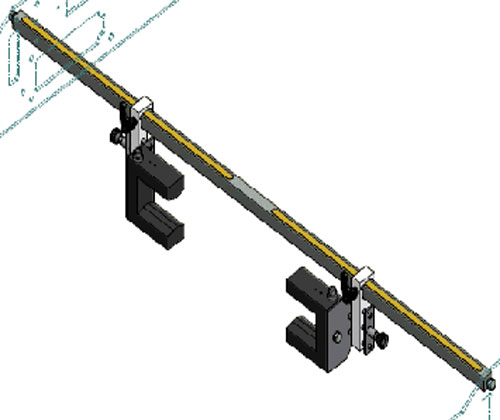

ZF010119 - Replacement of the wrapper infeed double belt with single belt

Machines: SK

Benefits: Efficiency increase - Technology update

This upgrade consists in the replacement of the wrapper infeed double belt with a new-generation single belt. The original system featured a wrapper infeed group with ...

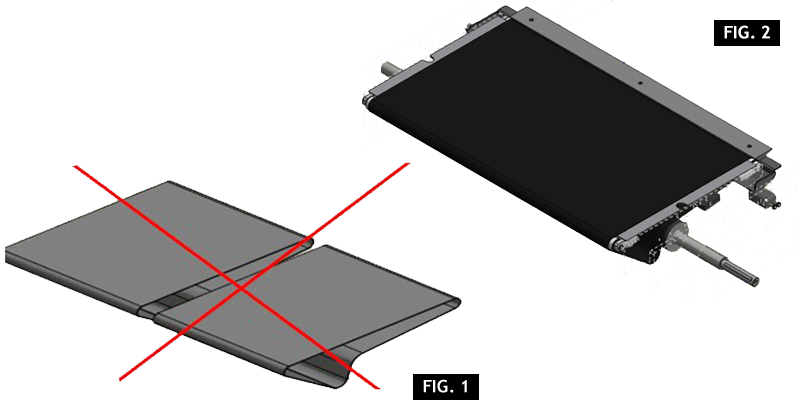

ZF010120 - Replacement of the belt plate with a long-life roller plate

Benefits: Efficiency increase - Technology update

This upgrade consists in the replacement of the belt plate with a new 'long-life' roller plate. The original system featured a complex-shaped plate on which the ...

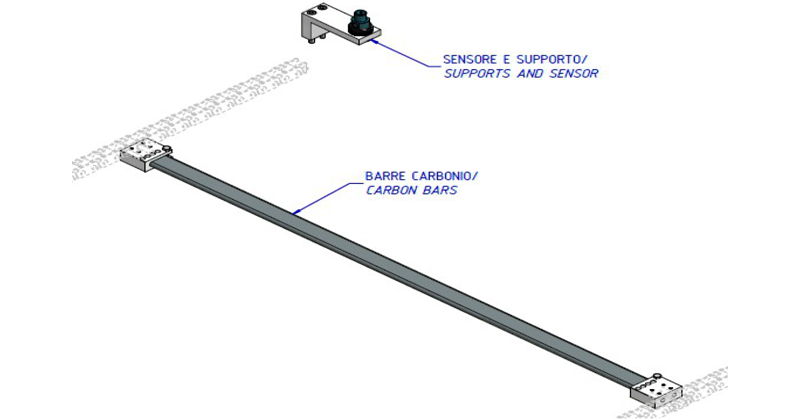

ZF010122 - Replacement of the wrapper bars with a carbon-made model

Benefits: Efficiency increase - Technology update

This upgrade consists in replacing the glass-fiber wrapper bars with carbon bars. Minimum requirements: This solution can be applied to all machines with wrapper ...

Contact us

- SMI S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40.111

- E-mail: info@smigroup.it

- Monday - Friday: 07:45 - 17:30

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

VAT nr: IT03942700166 - R.E.A. 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A.

IVA SMI INDUSTRIES Group

Headquarters: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Registered office: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

VAT: 04471940165 - TAX code: 03942700166 - R.E.A.: 421708

Share capital: Euro 5.000.000 i.v.